Introduction

Literature Review

Research Methodology

Overviews of the Deep Convolutional Neural Network

Framework for Evaluating Concrete Structure Performance using DCNN

Development of Concrete Structure Performance Evaluation Model using DCNN: Expected Effects

Discussion and Conclusion

Introduction

Concrete is a durable construction material. However, it is often reported that a concrete structure does not have sufficient durability. A material or environmental factor can decrease the durability of a concrete structure. If the decreased durability is not caused by environmentally induced deterioration, it may signify a problem with the material itself, which is a serious issue affecting the entire structure. Evaluation and prediction of decreased durability of a concrete structure is considered a critical research area.

If the degradation mechanism is determined to be a material factor, understanding that material can play an important role in improving durability. Empty spaces, or voids, scattered within a concrete structure occupy comprise the greatest aspect of the material factor affecting concrete durability. The size and shape of each void type, the contents in a unit diameter, and other distribution states are crucial for determining the concrete durability performance. The strength, which is one of the most important physical properties of the concrete material, also depends on the amount and sizes of the internal voids.

In the case of an environmental factor, the decrease in concrete durability due to chloride-induced corrosion is the first consideration. When the steel reinforcement within a concrete structure is corroded over time-and the reinfor-cement volume is thereby expanded, micro-cracks occur in the structure, which decreases the structural durability. This steel reinforcement corrosion is caused by intrusion of chloride from the reinforcement into the concrete.

Generally, the strength of a concrete structure is estimated by nondestructive inspection or core sampling, and the estimated strength is used to indirectly evaluate the durability. This method of evaluating durability may have limitations on account of the material complexity and minimized influencing factor. To overcome these limitations, image processing techniques are used to obtain images by means of a microscope and to analyze the obtained images. However, there is no clear rule or standard on the experimental procedure and accuracy of these techniques for analyzing the images.

Along with massive data and immensely increased computing power, deep learning methods have emerged. Deep learning is a machine learning techniques that opens a new paradigm of image analysis and utilization to overcome the limits of existing pattern recognition algorithms. A deep learning algorithm is an important artificial intelligence algorithm that enables performance improvement in various pattern recognition areas, such as image and voice recognition. In particular, the deep convolutional neural network (DCNN) deep learning method produces high-accuracy results on the basis of image data. It has thus attracted considerable research attention for its applications in many areas. For example, DCNN studies are being conducted in face recognition, aviation image analysis, and vehicle license plate identification. Moreover, in the construction industry, the application of DCNN techniques to identify cracks in wall and pavement are being examined.

Thus, to overcome the limitations of existing durability evaluation methods, a DCNN-based performance evaluation system model for concrete structures is proposed. This model is intended to establish a foundation for solving difficult problems in the construction industry.

Literature Review

Concrete is the most widely used construction material and is essential for maintaining structural stability. The decreased durability of concrete may result in the collapse of a structure; therefore, studies on concrete durability are being actively conducted from various perspectives. Chen et al. (2013) determined the compressive strength, splitting tensile strength, and flexural strength of cement mortar to study how porosity influences the magnitudes of these mechanical properties and the relationships among between. Park et al. (2012) studied water permeability in early-aged concrete at three days and modeled the crack effect on permeability. Yoo et al. (2016) presented a quantitative evaluation of the chloride diffusion coefficient considering the effects of cold joint and loading conditions. Song et al. (2009) proposed a numerical technique for chloride diffusion in high performance concrete (HPC) using a neural network algorithm.

Despite the above efforts, the complexity of concrete materials and the diversity of influencing factors have been obstacles to evaluating concrete durability. Thus, image processing techniques have been applied to solve these problems, determine concrete durability, and detect structural damage. Chen et al. (2015) demonstrated how developed motion magnification computer vision techniques can be used with high-speed camera video to visualize and quantify the vibrational mode shapes of simple structures. Cha et al. (2017) used an unscented Kalman filter as a nonlinear system identification method with the input of the displacement signals calculated from a video using a method related to phase-based optical flow processing. Nishikawa et al. (2012) presented a robust automated image processing method for detecting cracks in surface images of concrete structures. Yeum et al. (2015) proposed a vision-based visual inspection technique for automatically processing and analyzing a large volume of collected images. Alaknanda et al. (2009) discussed the application of morphological multistage watershed segmentation for detection of flaws in radiographic weld images. IT was determined that the internal concrete structure or cracks could be identified by the mere application of image processing techniques; however, the image data have limits in examining the durability performance and correlations.

Machine learning algorithms have been proposed to solve the above problems. Butcher et al. (2014) assessed two reinforced concrete structures, a laboratory controlled mesh reinforced concrete slab, and a real-world steel tendon reinforced floor using a technique known as EMAD to data capture, where automated detection of defects are sought. Jiang et al. (2007) presented a non-parametric system identification-based model for damage detection of high-rise building structures subjected to seismic excitations using the dynamic fuzzy wavelet neural network (WNN) model. O’Byrne et al. (2014) presented a regionally enhanced multiphase segmentation (REMPS) technique designed to detect a broad range of damage forms on the surfaces of civil infrastructures. Jahanshahi et al. (2013) introduced a contact-less remote-sensing crack detection and quantification method based on three- dimensional (3D) scene reconstruction (computer vision), image processing, and pattern recognition concepts.

DCNN techniques, in particular, have shown satisfactory results by effectively capturing image data. Simard et al. (2003) described a set of concrete best practices that document analyses that researchers can employ to obtain satisfactory results with neural networks. Soukup et al. (2014) trained CNNs on a database of photometric stereo images of metal surface defects for testing CNN recognition rates in image classification tasks. Cha et al. (2017) used CNNs to build a classifier for detecting concrete cracks from images. They built a robust classifier that is less influenced by noise caused by lighting, shadows, blur, and so on, and to secure a wide range of adaptability. Moreover, they built an initial test bed to enable other researchers to detect additional types of structural damage, such as voids, delamination, spalling, and corrosion of concrete and steel members. Zhang et al. (2017) proposed an efficient network architecture based on CNN for pavement crack detection on 3D asphalt surfaces with full consideration of pixel perfect accuracy. With consideration of the above advancements, and the limitations of existing durability evaluation methods described earlier, a DCNN-based concept model is herein proposed for evaluating concrete structure performance.

Research Methodology

Overviews of the Deep Convolutional Neural Network

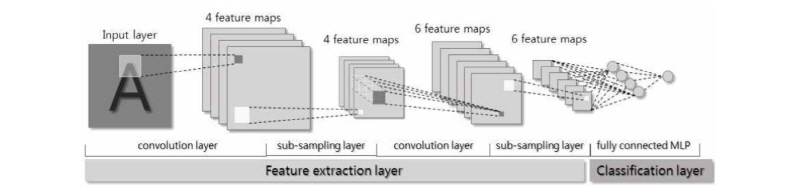

First suggested by LeCun in 1988, a CNN is a network model that shares weights among filters and includes subsampling 9]. CNN is a type of multi-layer perceptron that trains parameters of each layer by back-propagating errors from the final layer to the initial layer. Parameters are learned to extract features of high dimensions from numerous sample data. Unlike the conventional pattern recognition, features that are not changed by shifting, scaling, and distorting are automatically extracted. The network is trained and tested by the extracted feature input images, which is one of the advantages of CNNs. As shown in Figure 1, CNNs have a reiterated arrangement of two core structures: a convolution layer and a pooling layer. In the bottom layer, a fully connected layer is positioned. In other words, features are extracted in the convolution and pooling layers, and the classification is conducted in the fully connected layer. The convolution layer is the core of CNN. It creates a filter (or kernel) that extracts the most remarkable features of input images during the training phase. At that point, the weight-sharing in the feature map of the given layer reduces the number of parameters to be trained, thereby ensuring the learning efficiency.

Convolution layer

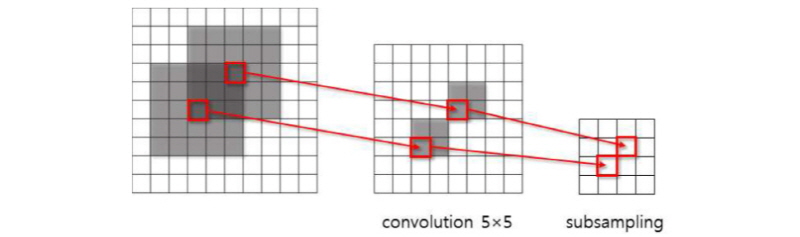

A convolution layer performs the convolution calculation of the input images and filter. In this layer, the corners, edges, and other feature layers of high dimensions are extracted. Multiple feature maps, which comprise a neural cell plane, are hence created. Figure 2 illustrates the convolution layer calculation. The left side is an input image; the right is the feature map extracted as the result of the convolution calculation. Each pixel of the feature map is the result of the convolution calculation with the kernel of the previous layer. The number of feature maps is the same as that of the filters in each convolution layer. The weight-sharing with the previous layer reduces the learning parameters of the neural network. Accordingly, the memory space necessary for storing parameters during training is reduced. The convolution calculation of each convolution layer enables the CNN to be free from shift and distortion.

Pooling layer

A DNN can be configured by connecting multiple convolution layers. However, subsampling is needed to obtain a feature map of a lower dimension. For example, if the convolution layer with 5×5 filter is connected to a 100×100 input image, a feature map with the size of 96×96 is created. Since the number of overlapped zones increases as the positions of the pixels are closer, this feature map has a similar pixel value. Figure 3 shows the convolution calculation and the subsampling procedure of pooling layer. The pooling layer reduces the feature map of the convolution layer. The feature map of a 48×48 size is output by subsampling the feature map of a 96×96 size by a filter of a 2×2 size.

The pooling layer decreases both the resolution and number of parameters to be learned. In addition, it offsets the slight deformation of the input image. A skipping factor exists that is not calculated in the pooling layer. This is called the “stride.” For example, if the stride is one, the calculation sequentially proceeds; if the stride is two, the calculation is conducted for every other pixel. Thus, the CNN includes the multiple combinations of convolution and pooling layers. This means a deep configuration of networks and is hence called a DCNN.

Framework for Evaluating Concrete Structure Performance using DCNN

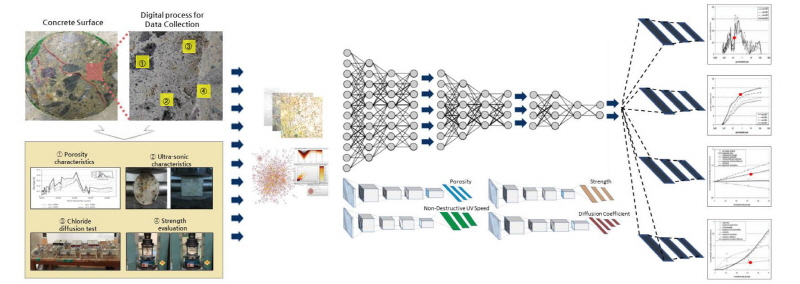

Figure 4 presents the concept of concrete performance evaluation using DCNN. As shown in the figure, the proposed performance evaluation model defines the surface image of concrete as the parameter of input data, and it employs a DCNN-based machine learning algorithm to produce the result of concrete performance as output data.

The proposed model can be developed in three phases. The first phase is the construction of the performance evaluation database. To implement the DCNN-based machine learning algorithm, the database must be built to consist of input and output data. The second phase designs a DCNN-based performance evaluation algorithm according to the characteristics of concrete. This phase defines the input layer, fully connected layer, convolution layer, pooling layer, and output layer of DCNN according to the concrete characteristics. It also conducts data advancement. The third phase implements the DCNN-based algorithm for evaluating concrete performance. In other words, the evaluation models for each data characteristic obtained from images are combined into a single DCNN model, and the algorithm is optimized.

The details of each phase are outlined as follows. As shown in Figure 5, the first phase constructs the database of the concrete performance evaluation. This model defines the voids, strength, and chloride diffusion coefficient-the focal points of existing studies-as the main factors affecting concrete performance. Moreover, the correlation between the experimental values of the performance and the surface image data of concrete specimens is also analyzed to obtain the concrete performance evaluation database. The concrete performance evaluation includes the MIP, strength test, acceleration test, and microstructure observation.

The existing experimental materials and data are segmented according to the necessity of inspecting each facility and the evaluation data for individual factors, such as the strength, porosity, and diffusion coefficient. However, this study matches various evaluation factors and all experimental results for each image to be used as input data so that the DCNN-based multidirectional performance evaluation algorithm can be developed.

As shown in Figure 6, the second phase designs DCNN-based performance evaluation algorithms for the characteristics of concrete. Initially, the data characteristics are analyzed for designing a model of the concrete performance evaluation. In other words, the concrete image data are used to derive a data distribution according to the characteristics, and data visualization analysis is performed. Next, data preprocessing of the DCNN model and a simulation are conducted to match the experimental data and output target values. Noise of the obtained data, such as visual deformation and contortion, is removed, inconsistencies are corrected, and the use of the neural network is verified. Finally, the input and output of the DCNN models are defined and the experiment is carried out to evaluate the performance. Thus, the input data structures, input forms, and output forms of the DCNN models are defined, the continuous parameter category is checked, and the data structure is designed. Accordingly, the neural network architecture for pursuing the performance target is designed.

|

Figure 6. Phase 2: DCNN-based performance evaluation algorithm design according to concrete characteristics. |

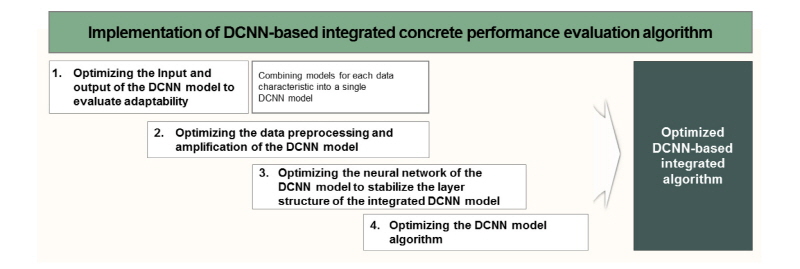

As shown in Figure 7, the third phase implements the DCNN-based algorithm for the concrete performance evaluation. First, the input and output of the DCNN model are optimized to evaluate adaptability. In other words, models for each data characteristic are combined into a single DCNN model. Next, the data preprocessing and amplification of the DCNN model are optimized to optimally approach a performance target value. Then, the neural network of the DCNN model is optimized to stabilize the layer structure of the integrated DCNN model. Finally, the correlation advancement is conducted between the concrete surface image and performance data, and the DCNN model algorithm is optimized. Accordingly, an optimized DCNN-based integrated algorithm, which has high accuracy and a fast processing speed for, is implemented for evaluating concrete.

|

Figure 7. Phase 3: Implementation of DCNN-based integrated concrete performance evaluation algorithm. |

Development of Concrete Structure Performance Evaluation Model using DCNN: Expected Effects

It is anticipated that the proposed DCNN-based concrete structure performance evaluation model will produce the following effects. First, the percentage of old facilities in South Korea built more than 30 years ago, which are subject to certain facility safety maintenance laws , will drastically increase from 9.5% in 2013 to 21.6% in 2023. In addition, by the end of 2012, approximately 4 million apartment buildings had been erected more than 15 years before that date. Such an explosive increase of old multi-family residential buildings will also increase both maintenance and performance evaluation costs. In South Korea, facility maintenance systems are revealing many problems and appropriate measures must be prepared. Basically, the durability evaluation of constructed structures should start from identifying the intrusion of deterioration factors and the mechanism of steel member corrosion. For this reason, it is very important to determine an effective analysis method. As explained, the proposed DCNN-based concrete structure performance evaluation model uses highly available image data and applies deep learning algorithms, thereby existing as a next-generation concrete performance evaluation technique. If accurate results are obtained from the proposed model, the current limitations of existing concrete performance evaluation systems can be incrementally solved.

Second, the proposed DCNN-based concrete structure performance evaluation model focuses on evaluating concrete performance. Nevertheless, it is also adequately flexible for its application to be extended using various data produced throughout the life cycle of a constructed structure. The accuracy of deep learning algorithms is basically improved along with the increase of input and output data. This is almost analogous to a scenario in which people make decisions on the basis of various experiences accumulated during a lifetime. This indicates that the key part of deep learning algorithms is constructing big data. With this consideration, deep learning algorithms can be applied to real-estate assessments and building energy management in the near future. The energy consumption of each building can be collected each second by sensors. For real estate, in particular, a large volume of data can been established. In addition, a wide range of areas, including process planning, construction cost management, resource input control, and optimal design, can benefit from deep learning algorithms by utilizing various construction and design cases.

Discussion and Conclusion

In the Republic of Korea, the majority of buildings and infrastructures were constructed in the 1980s and 1990s during a period of rapid economic growth. This is the main reason why the importance of maintaining constructed structures has been recently emphasized in that country. Concrete is a major material of those structures and is thus responsible for their stability and safety. Therefore, the existence of a technique for concrete durability evaluation is crucial.

In the first stage of the durability evaluation and design, the mechanisms of deterioration, factor intrusion, and steel member corrosion should be identified. Accordingly, if the relationship between the deterioration factors of concrete and durability can be readily evaluated, an advanced evaluation technique will be possible. In this paper, a performance evaluation system model for concrete structures was proposed. The model is based on DCNN. This model is intended to establish a foundation for solving difficult problems in the construction industry.

This study is significant because it responds to socio-environmental changes by combining the advanced technology of deep learning and the assessment of concrete material to develop a related evaluation technique. Nonetheless, it is not easy to determine the accuracy of the DCNN-based concrete durability evaluation technique. In the case of voids, studies are already using image data and thus significant results are expected. On the other hand, the applicability of DCNN to strength and chloride diffusion coefficient needs to be examined. The present research provides the important use of the deep learning technique. The accuracy of the deep learning technique depends on the amount of big data involved. By using this research, if a prototype of the DCNN-based concrete durability evaluation model is developed, and additional data are obtained to derive significant results for incomplete parts, a more advanced deep learning model can developed. Since such data can be secured by using various sensor techniques and knowledge-based database, further combinations of various technical areas will be possible.

In sum, this research is expected to engender positive effects in various research areas related to concrete construction. The proposed DCNN-based concrete durability evaluation model has not been completely developed; it remains in a concept phase. At the present time, the primary database construction is completed and the DCNN model is under development. When this DCNN model is completely developed, further studies will be conducted to verify the model viability and performance.