Introduction

Material and Methods

Material

Methods

Results

Depth of penetration

Compressive strength

Water absorption resistance

Water permeability resistance

Conclusions

Introduction

In recent years, penetrating water repellents have been applied to concrete surfaces in order to increase the service life of construction structures by preventing deterioration of concrete [1]. They have a role of effectively blocking water and salt, which penetrate from outside, by coating the surface of concrete or filling the micro-pores of concrete with a filler. However, in general, the penetrating water repellents used nowadays are of surface-application type and micro-pore filling type, and have limitations that exfoliation phenomenon occurs between concrete and polymer, and reacting with water, the surface is changed [2]. To overcome these limitations, penetrating water repellents of liquid type are researched and commercialized in the USA and Canada, whereby hydrophobic material penetrates inside micro-pores in concrete, by using the surface medication methods using silane and siloxane or the processing methods such as modified silicone resin synthesis. These are techniques that improve the durability of surface without having a separate protective layer on the concrete exterior. Moreover, they have an advantage in terms of solving the problems of conventional surface protection agents: secondary contamination caused by exfoliation and breakout, and loss of function of protection agent [3]. However, in the case of South Korea, the technology for manufacturing such a penetrating water repellent does not exist at all, and silane or siloxane is diluted in organic solvent or water and then used.

Therefore, as a part of research on the development of penetrating water repellent based on the cement reactive siloxane polymer, this study aims to evaluate the basic performance of concrete, to which the penetrating water repellent was applied.

Material and Methods

Material

Penetrating water repellency

This study fabricated reactive urethane prepolymer based on polysiloxane so that micro-pores of concrete can be coated, and fabricated candidate materials that have various particle sizes through molecule size control and surface modification. Among these, the candidate material that had the smallest particle size was selected, and through a post-treatment process, an oil-based penetrating water repellent, UP-40, and a water-based penetrating water repellent, UP-50C were fabricated.

Concrete

The mixing design of concrete for application of penetrating water repellent is shown in Table 1. In other words, the compressive strength was set at 18, 24, and 30 MPa, respectively, which are the levels usually used in concrete structures. For the cement, ordinary Portland cement that satisfies the quality criteria of Korean Industrial Standards (KS) was used, and for the coarse aggregate, crushed coarse aggregate that had the maximum dimension of 25 mm was used. For the fine aggregate, river sand of 5 mm or smaller was used, and for the admixtures, poly-carboxylate superplasticizer and AE agent were used.

Table 1. Mix Proportioning

Application methods of penetrating water repellency

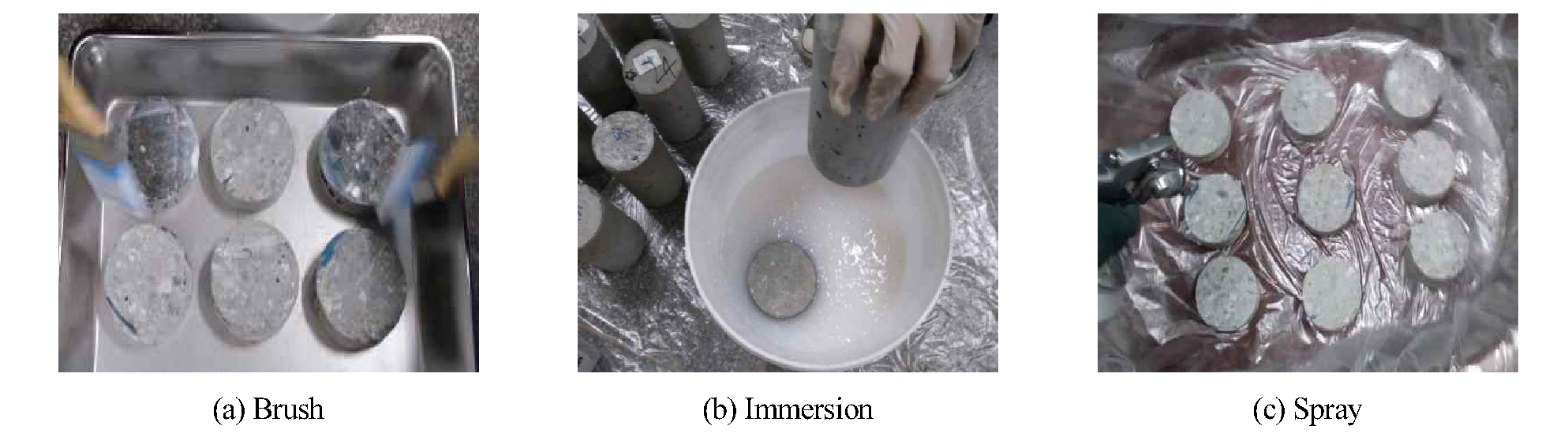

In this study, the application methods of penetrating water repellent are classified into brush, immersion, and spray application methods, as shown in Figure 1. The brush application method uses a brush to apply the penetrating water repellent of 0.5 L/m2 on a concrete surface twice in 30 min intervals, and afterwards, cures it at 20℃ for 24 hours. In the immersion application method, the concrete specimens are sufficiently immersed in a container in 30 min intervals, and then, cured at 20℃ for 24 hours. The immersion application method is usually applied to secondary products of concrete structure. The spray application method uses a compressor of 1 bar spray pressure to spray the penetrating water repellent of 0.5 L/m2 on a concrete surface twice in 30 min intervals, and afterwards, cures it at 20℃ for 24 hours.

Methods

Depth of penetration.

The principle of penetrating water repellent is that it penetrates inside and coats the concrete through micro-pores, and using the depth of penetration of penetrating water repellent, its performance can be estimated. Therefore, this study measured the depth of penetration of penetrating water repellent for the concrete specimens that had age of 28 days by applying the test standard specified in the KS F 4930 for the liquid type penetrating water repellent with respect to concrete surface application. Here, targeting the concrete specimens of 18 MPa, 24 MPa, and 30 MPa, the depth of penetration was measured according to the three application methods (brush, immersion, and spray methods) of penetrating water repellent [4].

Compressive strength.

To analyze the effect of application of penetrating water repellent on the compressive strength of concrete, the compressive strength test method of concrete specified in the KS F 2405 was used and the compressive strengths of concrete specimens were measured for each application method of penetrating water repellent [5]. In other words, circular specimens of ∅10×20 cm that have the specified strength of 18 MPa, 24 MPa, and 30 MPa were fabricated, and after curing them in a curing room of 20±3℃ temperature and 80% humidity for 21 days, they were cured seven more days in the curing room of same temperature and 50% humidity. Afterwards, the penetrating water repellents were applied using the different application methods, and after curing them in the curing room of 20±3℃ temperature and 50% humidity for 14 days, the compressive strength was tested.

Water absorption resistance.

To analyze the effect of penetrating water repellent on the water absorption resistance property of concrete, the water absorption resistance of concrete specimens were evaluated for the three application methods of penetrating water repellent according to the KS F 4930 [4], i.e., the liquid type penetrating water repellent standard for concrete surface application. In other words, the circular specimens of ∅10×20 cm having the specified strength of 18 MPa, 24 MPa, and 30 MPa were fabricated and after curing them in the curing room of 20±3℃ temperature and 80% humidity for 21 days, they were cured for seven more days in the curing room of same temperature and 50% humidity. Afterwards, the specimens were cut in 30 mm thickness and after applying the penetrating water repellent according to the three application methods, they were cured for 14 days in the curing room of 20±3℃ temperature and 50% humidity. The side of specimens that finished curing was waterproofed using epoxy, and in the water absorption coefficient measurement method of construction materials specified in the KS F 2609 [6], Equation (1) was used, thereby calculating the water absorption coefficient ratio in the standard state.

| $$WACR=WAC_{P\;}/\;WAC_O$$ | (1) |

Here, WACR denotes water absorption coefficient ratio, and WACP and WACO mean the water absorption coefficient (kg/m2·h05) of concrete specimen, to which the penetrating water repellent was applied, and the water absorption coefficient (kg/m2·h05) of the standard state concrete specimen, to which no penetrating water repellent was applied, respectively.

Water permeability resistance.

The water permeability ratio of water permeability resistance is a method of evaluating the penetration performance of moisture by applying the pressure of 1 N/mm2, unlike the natural moisture absorption measurement of water absorption resistance. To analyze the application of penetrating water repellent on the water permeability resistance property of concrete, this study evaluated the water permeability resistance of concrete specimens according to the three application methods of penetrating water repellent by using the test standard of liquid type penetrating water repellent for concrete surface application specified in the KS F 4930 [4]. In other words, just like the case of water absorption resistance, circular specimens of ∅10×20 cm having the specified strength of 18 MPa, 24 MPa, and 30 MPa, and after curing them in the curing room of 20±3℃ temperature and 80% humidity for 21 days, they were cured seven more days in the curing room of same temperature and 50% humidity. Afterwards, the specimens were cut in 30 mm thickness and after applying the penetrating water repellent according to the three application methods, they were cured in the curing room of 20±3℃ temperature and 50% humidity for 14 days. The side of specimens that finished curing was waterproofed using epoxy, and after applying the water pressure of 0.1 N/mm2 for 1 hour through a water permeability test device, the water permeability ratio was calculated by measuring the mass before and after the test.

Results

Depth of penetration

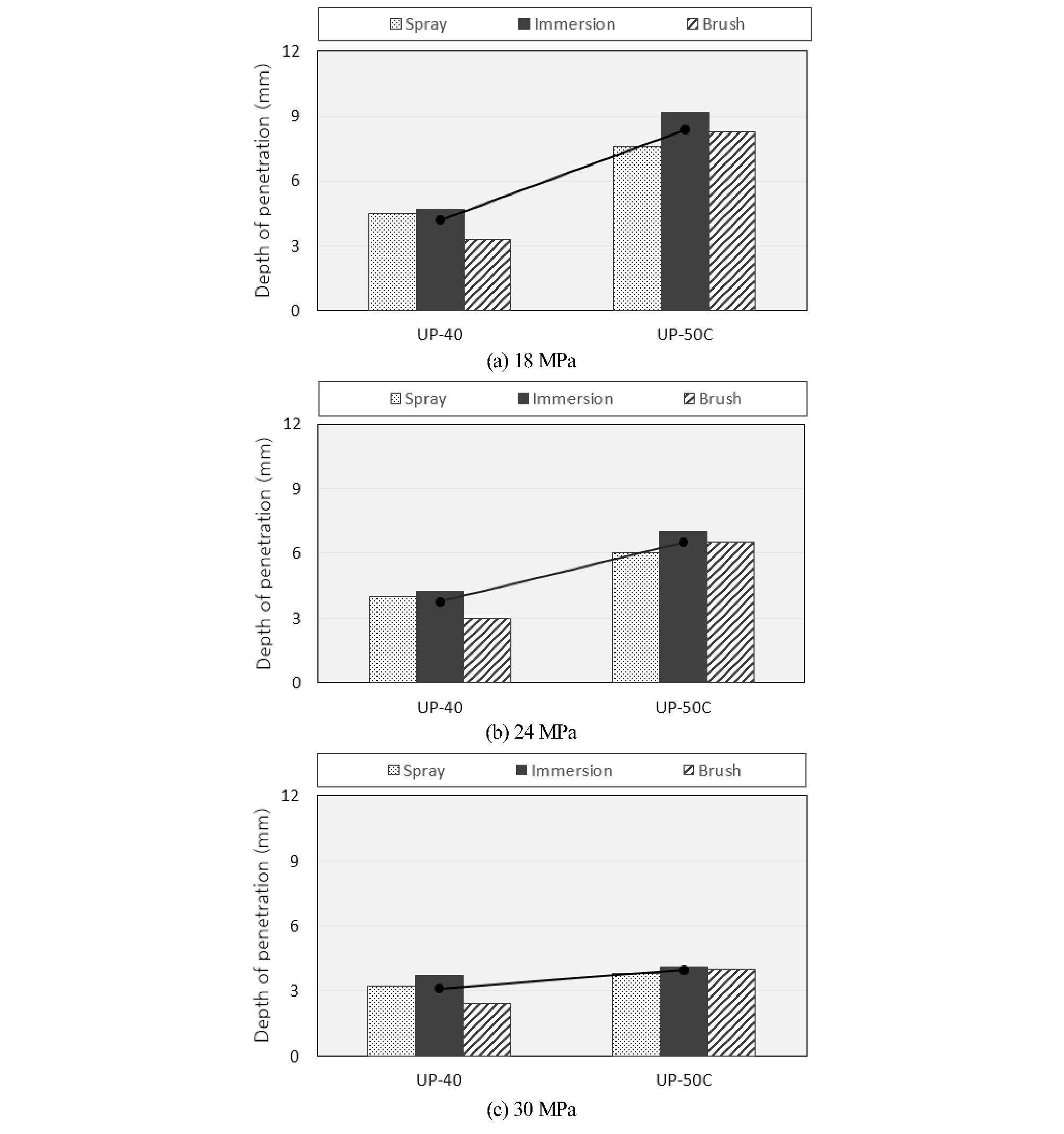

Figure 2 shows the evaluation results for the depth of penetration according to the mixing condition. In all the mixing conditions, the depth of penetration of penetrating water repellent was in the range of about 2.7-9.2 mm, and in general, the penetration performance of UP-50C, a water-based penetrating water repellent was better than that of UP-40, an oil-based penetrating water repellent. Moreover, according to the analysis, as the compressive strength of concrete specimen increased, the penetration performance of penetrating water repellent decreased generally.

The lowest depth of penetration was shown by UP-40, an oil-based penetrating water repellent, when the brush application method was used, while the spray application and immersion application methods exhibited similar penetration performances from each other. It is determined that the spray application method using 1 bar pressure helped smooth penetration of penetrating water repellent co MPared to the brush application method. On the other hand, in the case of immersion method, it is determined that sufficient penetration can be facilitated by immersing a concrete specimen in the penetrating water repellency solution for a certain period of time.

On the other hand, for the water-based penetrating water repellent, UP-50C, the depth of penetration was lower when the spray application method was used co MPared to the brush or immersion application method. It was due to the fact that the penetrating water repellent was not smoothly sprayed when the spray application was used because the water-based penetrating water repellent had higher viscosity than the oil-based penetrating water repellent.

Particularly, in the test scope of this study, the immersion application method showed the best penetration performance among the application methods of penetrating water repellent, and it was confirmed that the spray application method can be applied as well. The brush application method demonstrated some effectiveness but it was determined that verification would be necessary for actual application, and the emersion application method can be applied usefully when manufacturing secondary products (factory products) of concrete owing to the characteristics of application method.

Compressive strength

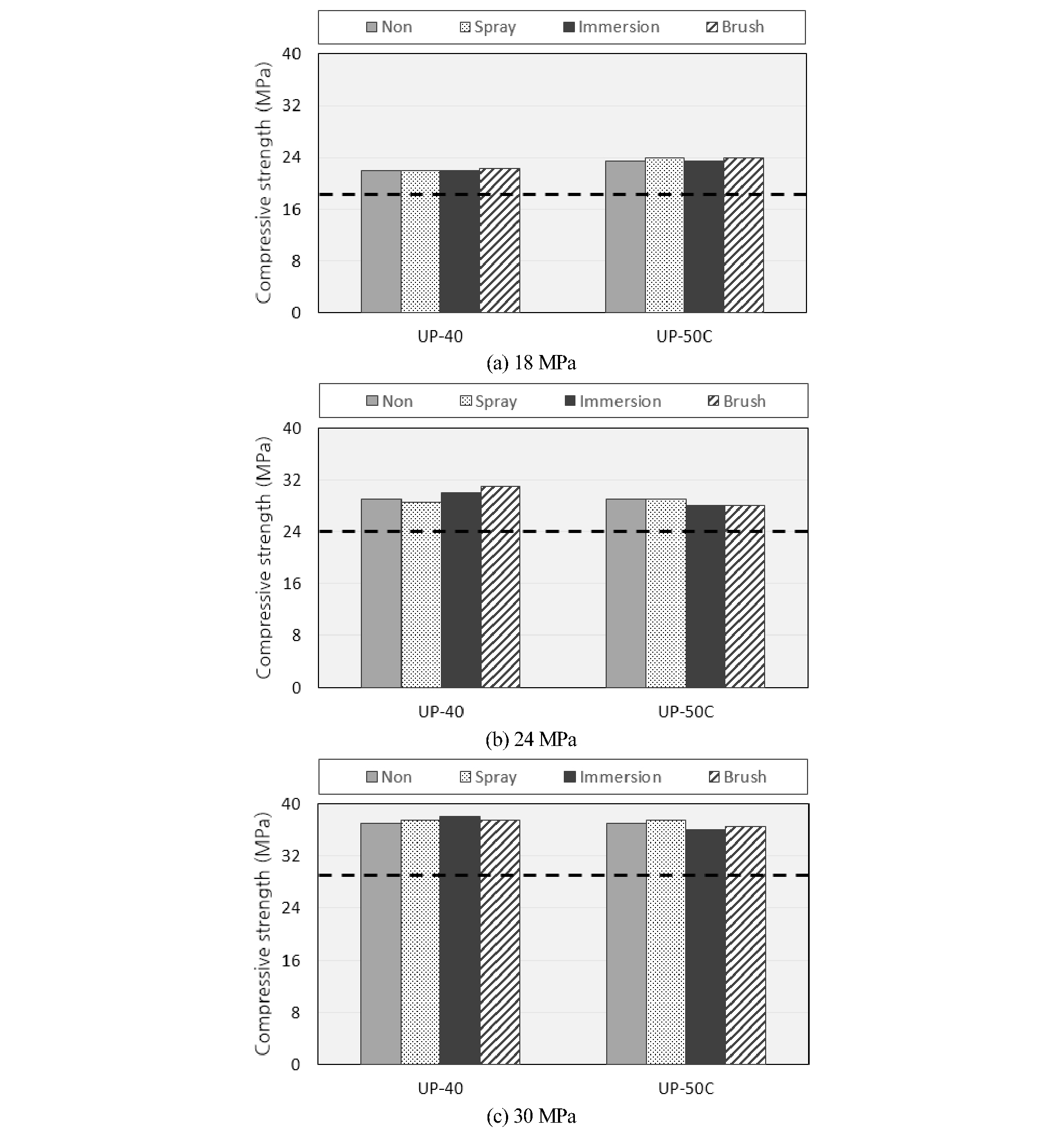

Figure 3 shows the evaluation results of compressive strength test according to the application/non-application of penetrating water repellent. According to Figure 3, the change of compressive strength was very small between application and non-application of penetrating water repellent. It was due to the fact that the penetrating water repellent was applied on day 28 when the strength development was completed for the specified strength of concrete specimens, and the strength was measured 14 days later.

Particularly, when UP-40, the oil-based penetrating water repellent, was applied to the concrete specimens, the strength showed an increasing trend although small, and when UP-50C, the water-based penetrating water repellent was applied to the concrete specimens, the compressive strength showed partially decreasing trend. This was because the hydration of concrete was hindered as the water-based penetrating water repellent that was mixed with anion surfactant penetrated and coated about 5-10 mm on the concrete surface and prevented moisture penetration.

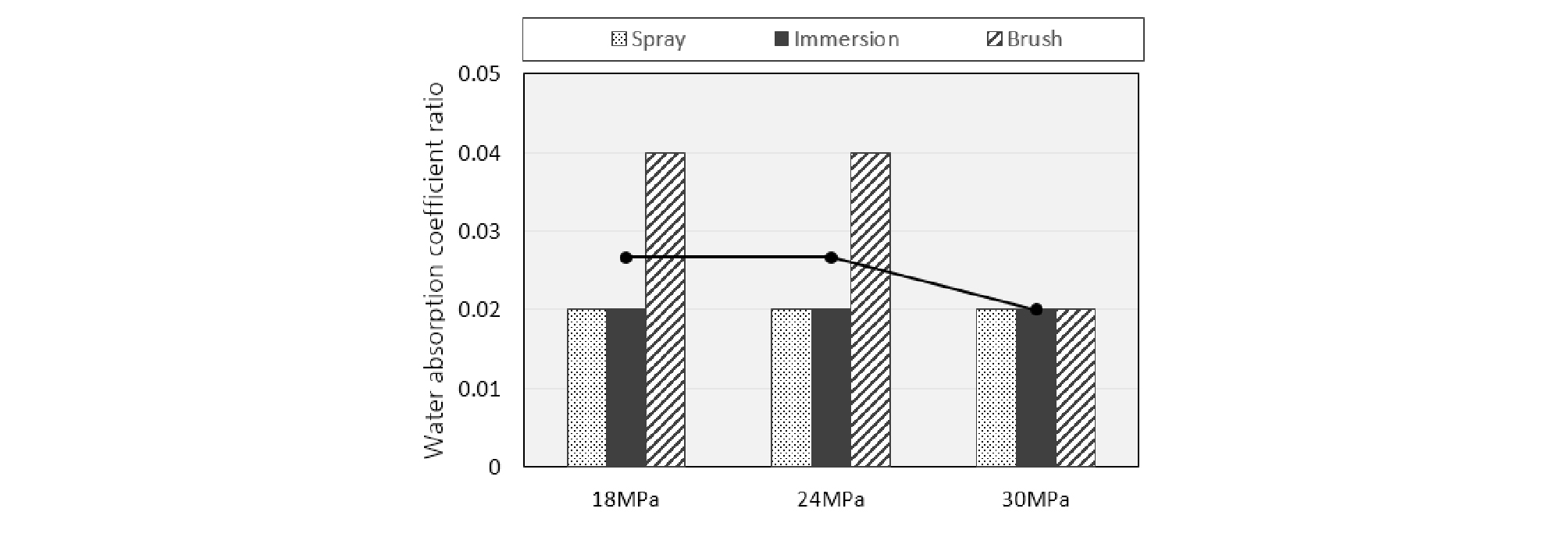

Water absorption resistance

Figure 4 shows the evaluation results for the water absorption resistance test. When the penetrating water repellent was not applied, the amount of water absorption of concrete specimens showed somewhat high values, 1.50-1.86 kg/m2, whereas the amount of water absorption after applying the penetrating water repellent was 0.04 kg/m2, showing a large decrease. It was determined to be due to the fact that penetration of moisture (water repellency) was prevented as the penetrating water repellent of concrete coated the micro-pores inside the concrete and formed a surface protection layer. On the other hand, in the water absorption resistance test and calculation results according to the KS F 4930, the standard state concrete specimens of 18 MPa and 24 MPa showed that the water absorption coefficient ratio was 0.04 when the penetrating water repellent was applied with the brush only, and when the spray application method or immersion application method was used, the water absorption coefficient ratio was 0.02, confirming excellent water absorption resistance. On the other hand, the standard state concrete specimen of 30 MPa had an excellent water absorption resistance with the water absorption coefficient ratio of 0.02 regardless of application method of penetrating water repellent. In future, it will be necessary to conduct a test for alkali resistance in addition to the water absorption resistance, and then, after performing resistance tests by repeating low and high temperatures, conduct the water absorption resistance test for post-accelerated weathering test.

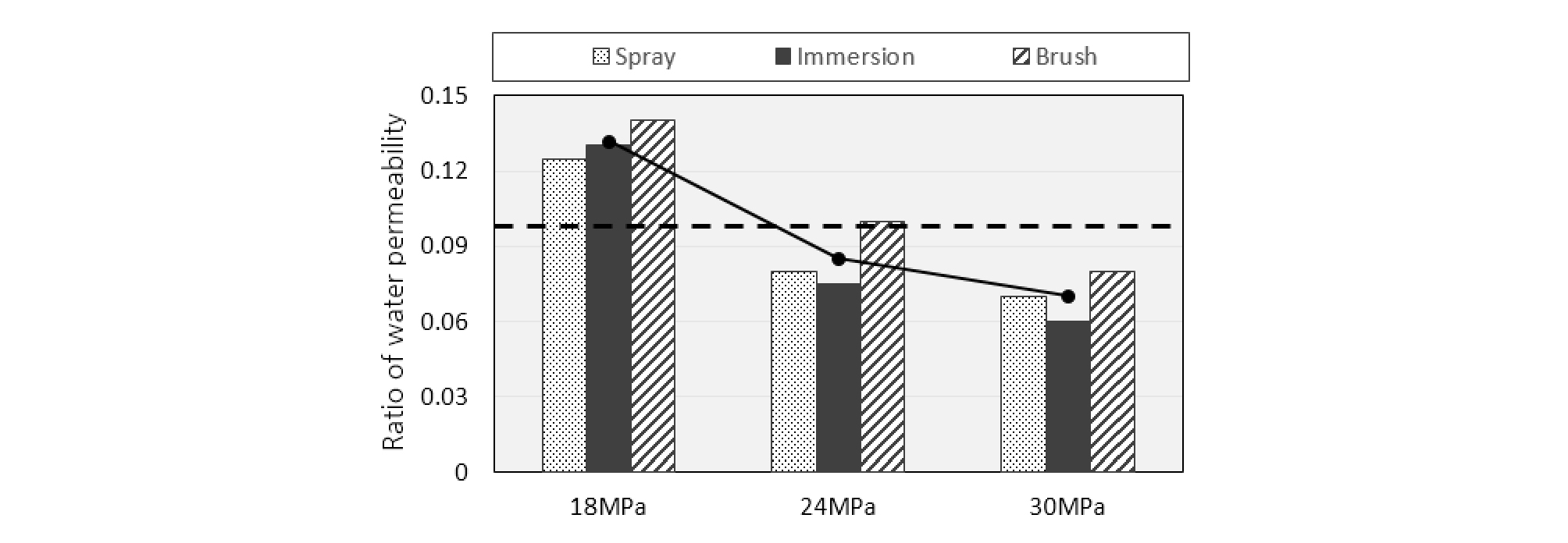

Water permeability resistance

Figure 5 shows the evaluation results for the water permeability test. In the test scope of this study, when the penetrating water repellent was applied, the concrete specimens of 24 MPa and 30 MPa generally satisfied the water permeability ratio of 0.1 or less, which was the standard of water permeability specified in the KS F 4903. However, when the penetrating water repellent was applied using a brush, the concrete specimen of 24 MPa exceeded the standard a little. Unlike the penetrating water repellent of regular silane coating concept, the penetrating water repellent of this study, which coats micro-pores inside the concrete, has an excellent water absorption performance, but is weak in terms of the water permeability resistance, which is evaluated by pressure when moisture penetrates. On the other hand, it was analyzed that all the concrete specimens of 30 MPa had excellent water permeability resistance regardless of application method of penetrating water repellent.

Conclusions

This study aimed to perform the basic application performance evaluation of concrete, to which the cement reactive siloxane polymer-based penetrating water repellent was applied, and obtained the following conclusions.

1. The depth of penetration of penetrating water repellent in all the mixing conditions was in the range of about 2.7-9.2 mm, and the penetration performance of UP-50C, a water-based penetrating water repellent was generally excellent co MPared to that of UP-40, an oil-based penetrating water repellent. Moreover, as the compressive strength of concrete specimen increased, the penetration performance of penetrating water repellent decreased in general.

2. The change of compressive strength was very small between application and non-application of penetrating water repellent. This was because the penetrating water repellent was applied at the age of 28 days when the strength development was finished for the specified strength of concrete specimens, and the strength was measured 14 days later.

3. When the penetrating water repellent was not applied, the concrete specimens showed the water absorption amount of 1.50-1.86 kg/m2, which was somewhat high. On the other hand, the water absorption amount after applying the penetrating water repellent was 0.04 kg/m2, showing a trend of large decrease. Furthermore, except for the case of applying the penetrating water repellents with brush, i.e., in the cases of using the spray application method or immersion application method, the water absorption coefficient ratio was 0.02, confirming excellent water absorption resistance.

4. The concrete specimens of 24 MPa and 30 MPa generally satisfied the water permeability ratio of 0.1 or less, which was the water permeability resistance standard specified in the KS F 4903. However, in the concrete specimen of 18 MPa and the brush method-applied concrete specimen of 24 MPa, the water permeability standard was exceeded. Therefore, in future, it will be necessary to improve the penetrating water repellent through the molecule size control and surface modification.