Introduction

Literature Reivew

Methodology

Construction Materials

Selection of LCIA Methodology

Result and Discussion

Conclusions

Introduction

The industry of practically every country is subject to increasingly strong international environment regulations based on the premise of a sustainable development. Accordingly, initiatives have been implemented by many countries to protect the environment through indirect regulation methods such as Environmental Product Declaration (EPD), in addition to direct regulations such as various emission standards [1], [2][3]. Following this trend, life cycle impact assessment (LCIA) techniques that provide quantitative environmental information, such as Particulate matter formation (PMF), for buildings are being developed in the construction industry. Although it has long been recognized that building construction activity forms an important source of PMF emissions Currently, The Cities/regions are developing the PMF data and air emission information in South Korea. Particularly just PM10 data is used in the fine particulate matters warning and alert. The data of PM10 NOx, SOx, NH3 based on LCIA, which have the PMF potential are not well considered. However, at present, the studies on the environmental database of construction materials are not sufficient to provide this support adequately. Also, the researches related with PMF potential based on LCIA are not conducted well [4], [5], [6].

Accordingly, this study aims to analysis of particulate matter of major building material production stage using life cycle impact assessment as part of an effort to develop an environmental database of construction materials.

Literature Reivew

Technologies related to the life cycle assessment (LCA) of construction materials use assessment methods that follow ISO 14040s, which is the international standard for LCA, and product category rules (PCR) are created for each country [7]. EPD systems are used as the effective decision-making assistance tool for the activation of eco-friendly construction materials by allowing architects or environmental performance assessors to choose construction materials from the member levels, such as the floor, wall, and ceiling, during the LCA of the building and reflecting the LCA results derived from each level to the eco-friendly building certification system.

EPD systems have specifically set the use scope, functional unit, and assessment scope according to the assessment criteria and raised the comparability between construction materials with the same functions. As recommended by ISO 21930, they are calculating the environmental impacts of construction materials by classifying them into 13 impact categories, including global warming and abiotic depletion. In addition, although the general purpose of the EPD assessment results is to provide the environmental information of each construction material, EPD is developed and used as the utilization data of the environmental performance assessment and certification systems for buildings. In particular, Germany and Sweden are assessing the environmental impacts of construction materials throughout the life cycle by constructing product category rules for construction materials, such as concrete and cement. PMF is the general term used to describe solid particles and liquid droplets found in the air. The composition and size of these airborne particles and droplets vary. Some particles are large enough to be seen as dust or dirt, while others are so small they can only be seen using a powerful microscope. Two size ranges, known as PM10 and PM2.5, are widely monitored, both at major emissions sources and in ambient air. PM10 includes particles that have aerodynamic diameters less than or equal to 10 micrometers (μm), approximately equal to one-seventh the diameter of human hair. PM 2.5 is the subset of PM10 particles that have aerodynamic diameters less than or equal to 2.5 μm. Impact substances include NH3, NOX, and SO2. PMF is calculated as the value of particulate matters, which are the reference substances of particulate matter formation, by applying the particulate matter formation provided by ReCiPe. They are assessing even the emission and absorption of environmental impact factors during operation. Furthermore, the case of the UK expanded EPD to the building unit assessment level and has a very effective frame for the activation of eco-friendly construction materials because EPD also has the function as the input data of members and buildings (Table 1) [8], [9], [10], [11].

Table 1. Environmental product declaration for construction materials of environmental labelling

In South Korea, interest in the LCA of the construction material industry is increasing, but the impact category of construction material LCA is currently focused on the assessment of carbon dioxide emissions from a global warming perspective. As the system boundary also regards construction materials as intermediate products to construct a building, cradle-to-gate assessment of construction materials is dominant instead of the life cycle perspective [12]. However, considering the nature of the construction material industry closely related to human residence and social activities, it is necessary to avoid the limited LCA from a global warming perspective and to perform assessment for various environmental impact categories, such as abiotic depletion, acidification, ozone depletion, eutrophication, and photochemical oxidant creation, according to the purpose of LCA. LCA needs to be enabled for stages following production.

Methodology

Particulate matter formation, a recent environmental issue, has been identified as a potential cause of serious damage to the human body through penetration into the respiratory tract and skin. Therefore, the PMF stipulates that the items are subject to atmospheric environment management. For the life cycle environmental impact assessment of building materials, it is prerequisite to establish the environmental impact coefficients of raw materials and energy sources which are to be put into a building material throughout the life cycle. The environmental impact coefficient refers to those quantified values of environmental impact in accordance with the functional units of each product based on the life cycle inventory database (LCI DB). Herein, the LCI DB is a pre-listed inventory data that is included the quantities of resources (naturally collected resources, energy and minerals) that are to be fed into a product system, emission quantities that are released into the environment (air system and water system) and about waste products in accordance with the functional units of each product. This study established the environmental impact coefficients of construction materials in particulate matter formation potential impact categories.

Construction Materials

To select the major building materials used in apartment buildings, the building materials which are stated in bill of quantities were connected with the same or similar materials from the environmental impact coefficient (refer to Table 2). This study, also, evaluated the PMF environmental impact of production stage of evaluated. The PMF of building materials can be established by LCIA based on LCI DB. This study applied the Korea LCI DB presented by the Ministries of Environment and Knowledge Economy (the predecessor of the current Ministry of Industry, Trade and Resource), and the National D/B for Environmental Information of Building Products by the Ministry of Land, Transport and Maritime Affairs (the predecessor of the current Ministry of Land, Infrastructure and Transport) as LCI DB of construction materials. This study selected LCI DB in the order of regional relevance, temporal relevance, and technical relevance, in accordance with the LCI DB selection guideline of specified in ISO 14040 [12]. Formula 1 represents the equation for environmental impact coefficient using LCI DB of construction materials.

| $$PM_i=\sum PM_{i,j}=\sum(Load_j\cdot eqv_{i,j})$$ | (1) |

Table 2. LCI DB connection by building materials

Here, PMi is the size of characterized environmental effect of , Loadj is the environmental load of the jth influential substance, and eqvi,j shows the impact index of the jth influential substance belonging to the effect category of i.

Selection of LCIA Methodology

For the estimation of the environmental impact coefficient of construction materials, it is necessary to select a LCIA methodology that can scientifically identify the correlation between environmental impact substances and impact factors according to environmental impact categories.

As environmental impacts can occur in various ways depending on types of environmental impact categories and regional environments, various LCIA methodologies have been suggested by many countries and researchers [13], [14]. As part of a strategical measure to utilize the environmental assessment results about those construction materials which already obtained the EPD certificates issued by the Korea Environmental Industry and Technology Institute as the DB of this study, the same LCIA methodology as the current EDP certification system was applied by this study. PMF can be estimated in the base substance ‘PM10’ based on universally applicable impact factors suggested by ReCiPe 2009.

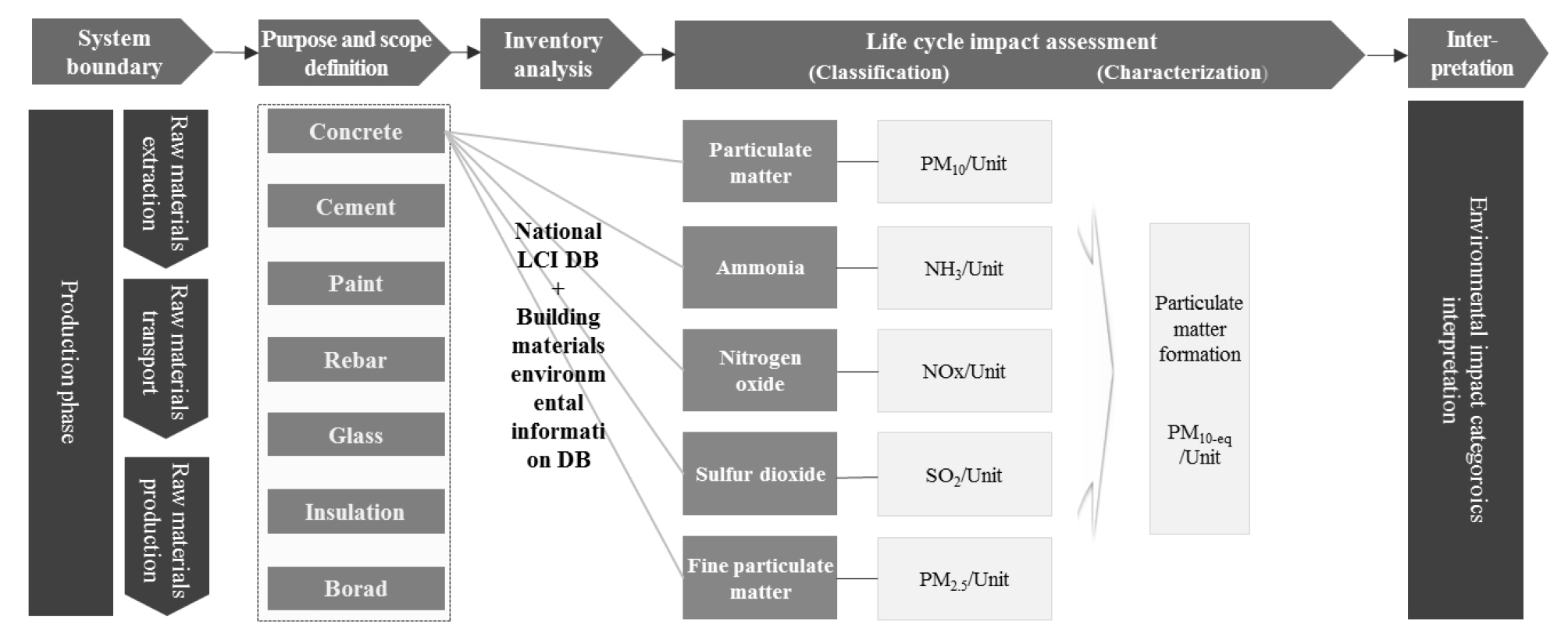

PMF refers to air pollutants whose particle size is 10 μm or less when the product is disassembled / disassembled. The influent substances are classified into ammonia (NH3), nitrogen oxides (NOx), and sulfur dioxide (SO2) which is the base substance based on the impact indexes suggested by the CML 2002 [15], [16], [17]. Figure 1 indicates the methodology of life cycle impact assessment.

Result and Discussion

The classification consists of two processes: the classification process and the gathering process of environmental impact substances. Based on those LCA methodologies which were reported by the relevant scientific literatures, the influence of each environmental impact substance on the Earth’s environment became clarified in the classification process and the gathering process of the environmental impact substances drawn from the LCI DB in accordance with environmental impact categories.

As seen in Table 3, this study classified the environmental impact substances into the corresponding environmental impact categories. Table 3 shows the breakdown of the LCI DB-based classification about the building materials of the ready-mix concrete 25-240-15 as follows: electric steel deformed bars, paint water type, and plate glass. Despite that, as the environmental impact substances use different impact factors, the quantification of impact levels has limitations. Through characterization, which is to multiply the emissions of the environmental impact substances by the impact factor of each environmental impact category and add them up, the environmental impact coefficient of construction materials can be quantified.

Table 3. PMF Impact factor and reference material

| Emitted substance | CAS No. | Unit | Particulate Matter Formation Potential (PM10-eq/unit) |

| PM10 to air | 111-87-5 | kg | 1 |

| NH3 to air | 111-66-0 | kg | 0.31 |

| NOx to air | 629-62-9 | kg | 0.21 |

| SO2 to air | 109-67-1 | kg | 0.19 |

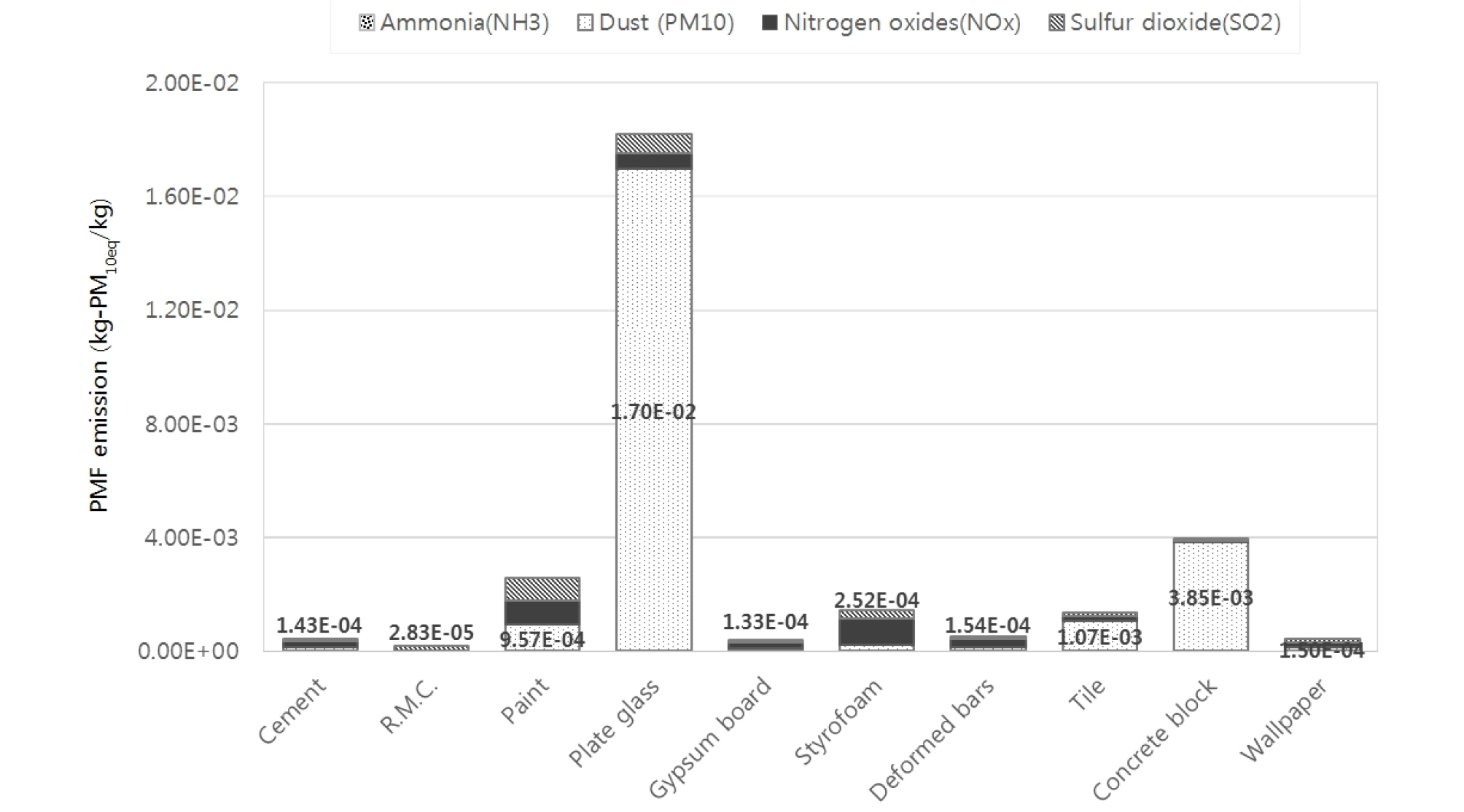

For instance, the impact factors of PM10, NH3, NOx and SO2, which are the base substance and the environmental impact substances of PMF, are as follows: 1.00E+00 kg-PM10/kg- PM10, 3.10E-01 kg- PM10/kg- NH3, 2.12E-01 kg- PM10/kg- NOx, and 1.91E-01 kg PM10/kg- SO2. As shown in Figure 2, the amount of PMF emission factor was the most in plate glass (1.70E-02 kg-PM10-eq/ kg). It was analyzed that PM10 was generated in the electric furnace for manufacturing glass products made of silica sand and crushed glass.

By multiplying them with the classification breakdown 1.70E-02 kg-PM10-eq / kg ; PM10, 9.10E-05 kg-PM10/kg ; NH3, 5.51E-04 kg-PM10/kg ; NOx, and 1.91E-01 kg-PM10/kg of Plate glass and adding them up, it is possible. Meanwhile, the environmental impact of construction material in the same category was analyze based on the characterization impact which was calculated in this study. Through this, it is believed to effectively support the decisions of stakeholders to improve the environmental performance of buildings and provide a basis for voluntary participation of architects in environment consideration activities.

Conclusions

This study aims calculation of particulate matter of major building material Production phase using life cycle impact assessment as part of an effort to develop an environmental effect assessment method for buildings material, and the following conclusions were derived.

1) For the establishment of environmental impact coefficients of particulate matter formation, 4 kinds of environmental impact categories, such as PM10 to air, NH3 to air, NOx to air and SO2 to air were selected.

2) Also, to facilitate the life cycle environmental impact assessment, the Korea LCI DB and the National D/B for Environmental Information of Building Products were utilized to establish the environmental impact coefficients of particulate matter formation. In this study, establishment of environmental impact coefficients of major construction material by complying with ISO 14040.

3) The amount of PMF emission factor was the most in plate glass (1.70E-02 kg-PM10-eq / kg). It was analyzed that PM10 was generated in the electric furnace for manufacturing glass products made of silica sand and crushed glass.

4) Through this, it is believed to effectively support the decisions of stakeholders to improve the environmental performance of buildings and provide a basis for voluntary participation of architects in environment consideration activities.