Introduction

Background

Environmental Impacts of Bridge Maintenance

Bridge maintenance data

Estimation of Environmental Impact Prediction Model for Bridge Maintenance

Estimation of Frequency by Maintenance Method Using Data Mining

Annual Maintenance Calculation of Bridge

Investigation of input materials by bridge maintenance method

Equation Model for Environmental Impact Calculation of Bridge Maintenance and Result

Discussion

Conclusion

Introduction

When evaluating the environmental impact of a structure over the course of its lifetime, the maintenance of the structure is an important process that must be considered during its use phase. However, in the case of a bridge, characterizing these maintenance events before they occur is difficult, because bridge maintenance is usually performed after damage has occurred.

Recently, to manage the maintenance of bridges systematically, the history of bridges pertaining to the maintenance operation, frequency of maintenance, inspection information, and cost data, has been organized in the form of a database called the National Bridge Maintenance System [1]. This database contains information regarding bridge maintenance events that have already occurred, which can be used to facilitate decision-making with the goal of rationally estimating and reducing the environmental impact and cost for future maintenance.

This study presents an equation model for predicting the environmental impact of bridge maintenance using data mining in an evaluation of the impact on the life cycle of bridges through life cycle assessment. The datasets used in this study were summarized, and the factors affecting the prediction of the environmental impact of the maintenance process were extracted through data mining. Consequently, the equation model was derived from the extracted elements, and the annual environmental impact of the road bridge maintenance process was determined by applying Korean road bridge data to the equation model.

Background

Environmental Impacts of Bridge Maintenance

The environmental impact of material production and bridge construction have been actively studied [2, 3, 4, 5, 6, 7, 8]. However, there is a lack of research on environmental impact caused by bridge maintenance. Moreover, predicting future maintenance events is difficult, because the maintenance cycle may vary based on the environmental and structural characteristics of the country in which the bridge is built and the different maintenance methods used. Accordingly, various bridge life-cycle assessment (LCA) studies have included the derivation of environmental impacts on the assumption of limited conditions for bridge maintenance.

In existing studies, the method used to calculate the maintenance environmental impact assumes the maintenance cycle most commonly used. However, this is probably different from the actual maintenance event during the lifetime of the bridge, because the actual environment in which the bridge is constructed and the characteristics of its use are not considered. Therefore, this study aims to propose a model that calculates the annual average environmental impact of bridge maintenance by using the maintenance history data collected in a particular country.

Bridge maintenance data

To manage elements of infrastructure (such as roads and railways) systematically, systems for collecting and managing the current status and maintenance history of structures (such as bridges and tunnels) are being developed worldwide. The data collected through these systems exist in the form of various datasets, and these datasets are actively used for studies on the status analysis of bridges, traffic, and cost prediction.

The U.S. National Bridge Inventory (NBI) from the Department of Transportation (DOT) is one of the most representative bridge maintenance datasets [9]. The DOT has been managing bridges through the NBI since 1992 and is updated annually for accurate and systematic bridge management. The NBI dataset records data on a total of 615,002 highway bridges (as of 2017), and codes and manages a total of 137 categories of information on each bridge, including construction year, use, and structure type. Information on maintenance, including the condition of the deck, substructure condition (including pier and abutment), and the superstructure condition of the bridge, are recorded [10].

In Korea, the Ministry of Land, Infrastructure, and Transport provides status information on bridge extension and annual opening through a road bridge and tunnel status information system. The Bridge Management System (BMS) established in Europe and the United States is benchmarked to manage bridge information and accumulate maintenance data for the entire life cycle of the bridge [11, 12].

In particular, through the Road Statistics and Maintenance Information System operated by the Ministry of Land, Infrastructure and Transport, datasets of performance statistics on road maintenance costs from 1977 to 2017 are available to the public [13]. In addition, the Korea Expressway Corporation operates a highway public data portal to disclose various data collected on highways for utilization by private users [14].

In this study, the road data and repair cost performance dataset by the Ministry of Land, Infrastructure and Transport's “Road Bridge and Tunnel Status Information System” and “Road Statistics and Maintenance Information System” were used for analysis.

Estimation of Environmental Impact Prediction Model for Bridge Maintenance

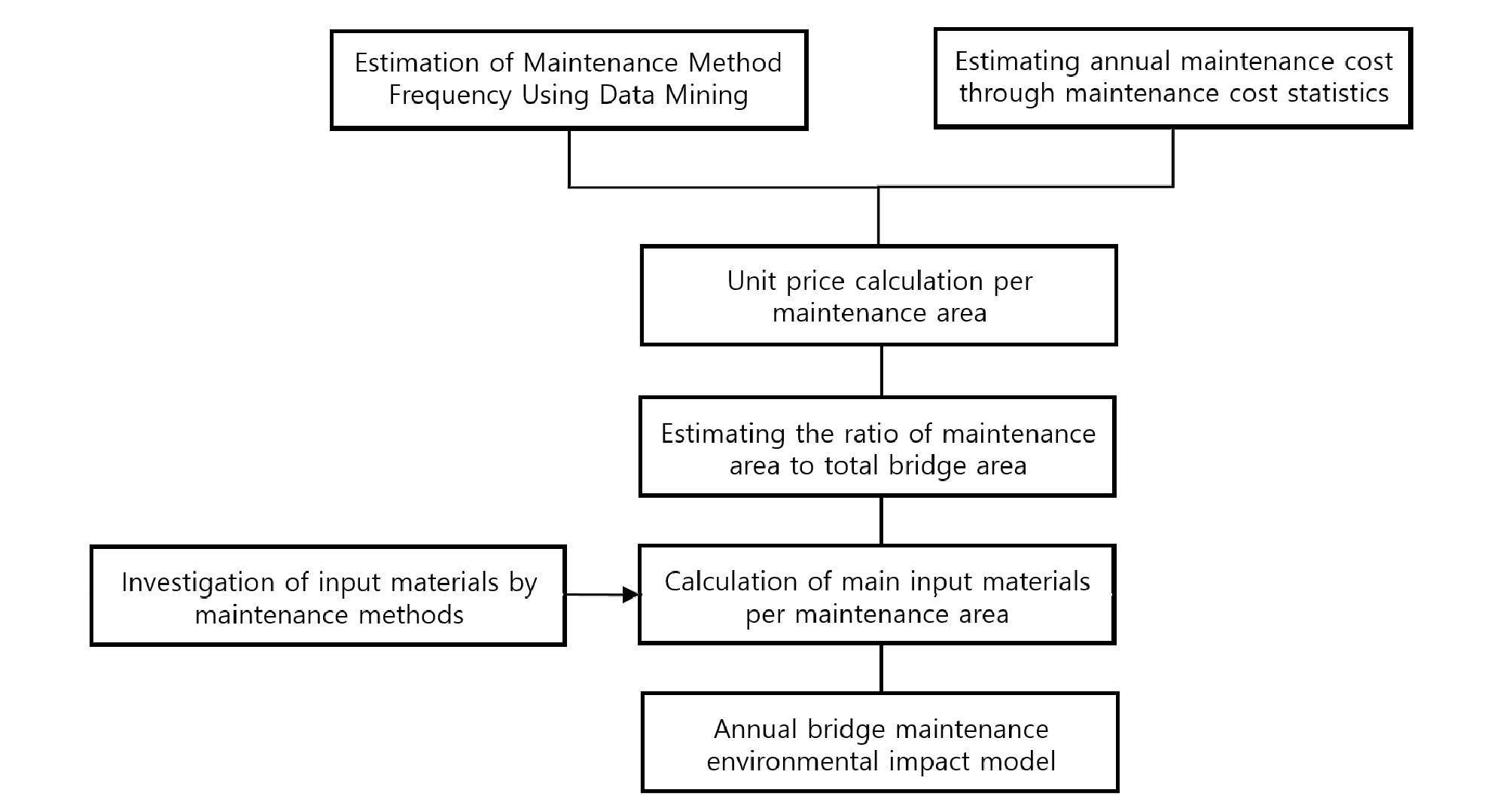

Because bridge maintenance is performed by selecting a method after diagnosis, it is difficult to predict the maintenance of the bridge accurately before maintenance becomes necessary. However, bridge maintenance datasets can be used to analyze historical data, such as bridge maintenance cost, performance method, maintenance site, and unit cost, to build a life cycle prediction model for new bridges. The methodology of the environmental impact prediction model for bridge maintenance is shown in Figure 1.

Estimation of Frequency by Maintenance Method Using Data Mining

In this study, the frequency of each construction method in the maintenance phase of the bridge was calculated by using the data from the Korea Highway Corporation road bridge maintenance dataset. The dataset consists of a total of 215, 270 maintenance performance data elements collected on highway bridges and contains information regarding the parts that were used and methods that were performed. As a result of refining the dataset by removing the missing data, the valid data elements were total 137, 292.

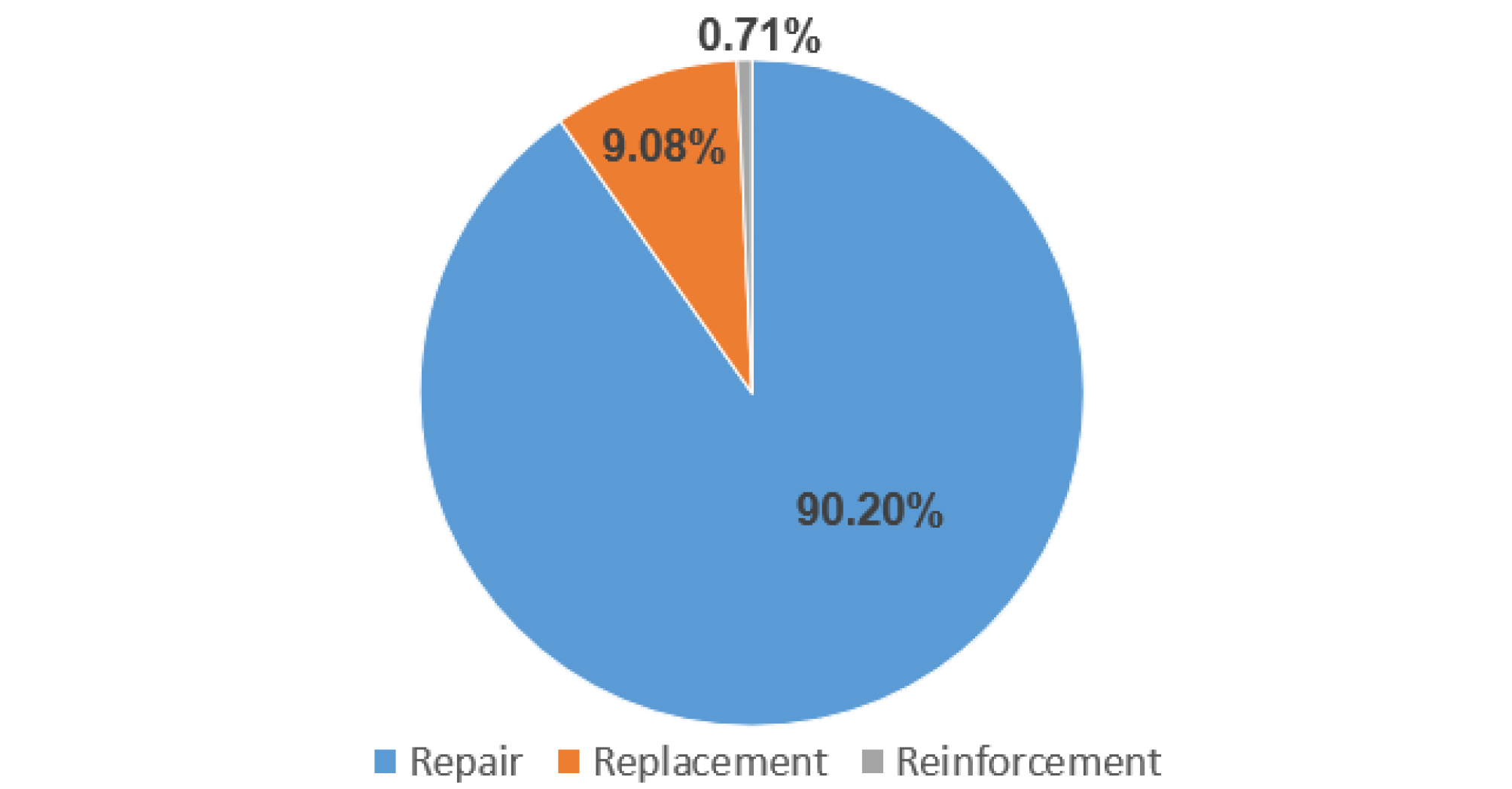

The data from the bridge repair performance datasets were classified according to the maintenance method and categorized into three types: repair, replacement, and reinforcement. The maintenance method differs depending on the damaged part of the bridge and the degree of damage, which affects the frequency of maintenance and input material used in the maintenance. The frequency of maintenance method usage based on the bridge maintenance data is shown in Table 1, and the ratio of each maintenance method is shown in Figure 2.

Table 1. Frequency of maintenance methods

| Classification | Total | |||

| Repair | Replacement | Reinforcement | ||

| Frequency | 123,842 | 12,470 | 980 | 137,292 |

| Ratio (%) | 90.20% | 9.08% | 0.71% | 100.00% |

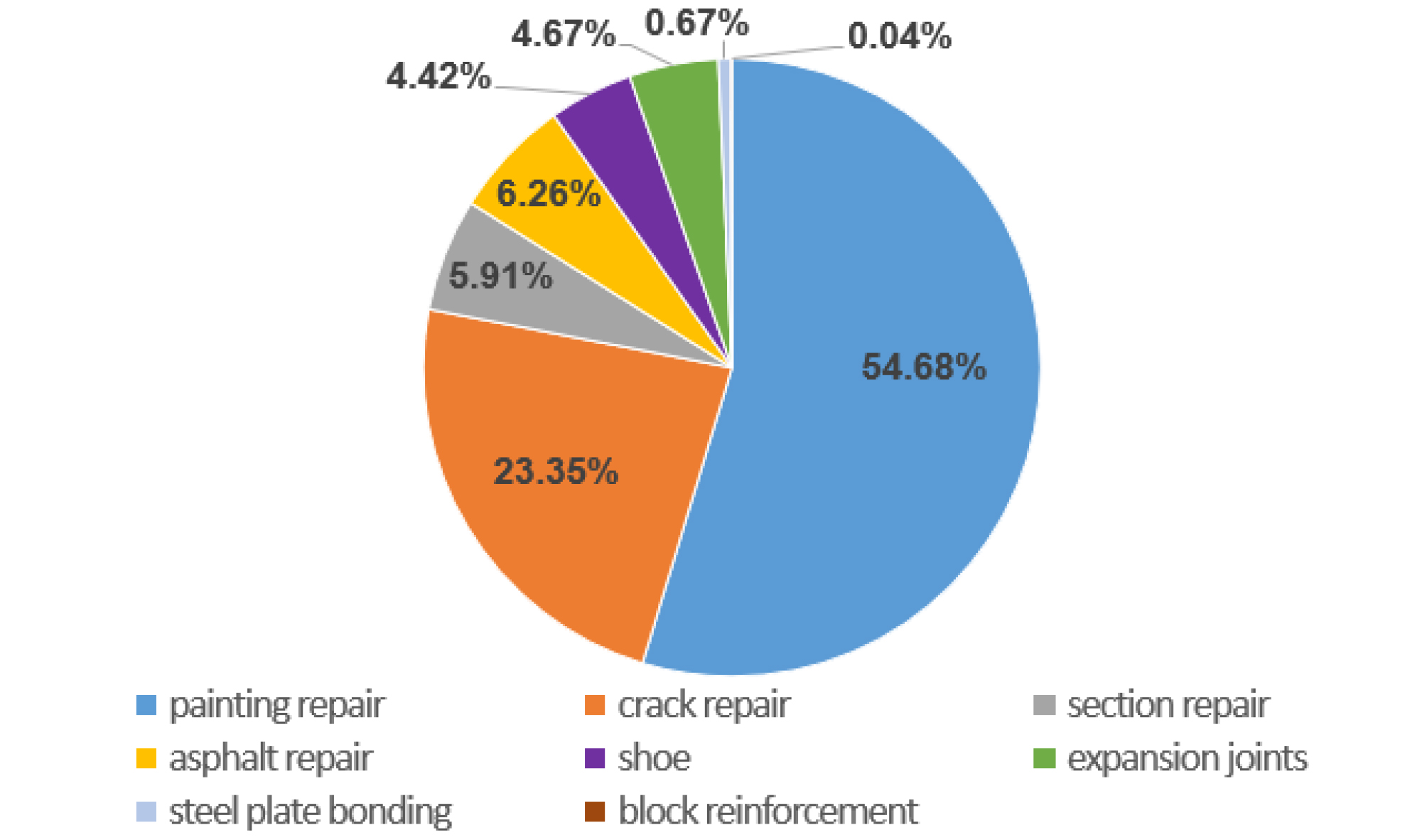

The major repair methods considered were painting repair, crack repair, section repair, and asphalt repair. In particular, the frequency of paint repair and crack repair was high. This means that the frequency of repairing relatively minor defects in bridge repair is higher than the frequency of repairs that preserve structural durability, such as cross-sectional repair. In the case of replacement, shoe and expansion joints were considered as major replacement sites. Particularly, expansion joints showed that the monocells were replaced with the highest frequency among the various types of joint replacement. Representative methods for bridge reinforcement were steel plate bonding and block reinforcement. In particular, the frequency of the steel plate bonding method was the highest in bridge reinforcement. Table 2 shows the results of analyzing the frequency of each maintenance method using the road bridge maintenance dataset.

Table 2. Analyzed frequency of maintenance methods

Figure 3 shows the ratio of each maintenance method performed during the data collection period, which can be used to predict the performance frequency of each method for maintenance during the life cycle of a bridge.

Annual Maintenance Calculation of Bridge

In this study, the maintenance costs of bridge structures were collected and analyzed based on the “Road Statistics and Maintenance Information System” dataset. The data from 1977 to 1985, when the total length of the bridge was omitted, and the data from 2012, when the cost was missing, were excluded; the remaining dataset was refined.

Maintenance costs are amounts that have been set for each year and must be converted to their present value. As a method of converting the present value, the producer price index (PPI) of the National Statistical Office (2010) was examined. The present value conversion equation model is shown in (1). In this study, the annual maintenance cost converted to the 2017 standard was calculated through the equation.

| $$Value_{standard}=Value_{year}\times PPI$$ | (1) |

Valuestandard : Standard year converted value (won)

Valueyear : Year value (won)

PPI : Producer Price Index

Meanwhile, to calculate the unit price per unit area for each construction method, the Korea Institute of Applied Statistics (KORIS) 2017 price distribution data were used [15]. The total unit cost per unit area of the maintenance work was calculated by applying the weighting factor based on the frequency of the maintenance method to the unit price of each method. The equation model for calculating the unit price per unit area of maintenance work is shown in (2).

| $$Cost_{unit}=\sum_{i=1}^nc_ir_i$$ | (2) |

Costunit : Unit price per unit area of maintenance work (won/m2)

Ci : Unit price per unit area by maintenance method (won/m2)

ri : Weighting factor (Frequency ratio of maintenance method)

n : Maintenance method type

The unit price per unit area of maintenance work is an estimate of the amount incurred when maintenance work corresponding to an area of 1° m2 is performed. Through this, the estimated total area for annual maintenance was calculated. The average width of the bridges was calculated by using the standard road map of the Korea Expressway Corporation. The average width of the bridges was 19.8° m.

The ratio of the maintenance area to the total area of the bridge calculated as Table 3 is a value that predicts the ratio of the maintenance area to the total area of the bridge over 1 year. An average maintenance rate of 3.36% was calculated.

Table 3. Ratio of maintenance area to total bridge area

Investigation of input materials by bridge maintenance method

To calculate the environmental impact of maintenance work in the maintenance phase of bridges, an examination of input materials used for each construction method is required. In this study, the representative materials introduced by each method were considered, as shown in Table 4, based on the price distribution for each method.

Table 4. Representative materials by maintenance method

Because the quantity of materials input per unit area of maintenance depends on the frequency adopted in the construction method, it should be calculated by applying the weight according to the frequency of each construction method as in the process used to obtain the unit price per unit area of maintenance construction.

Equation Model for Environmental Impact Calculation of Bridge Maintenance and Result

The environmental impact of maintenance over the life cycle of a bridge can be estimated by calculating the average annual environmental impact value. In this study, the model for the annual average environmental impact of bridge maintenance is derived as in (3).

| $$I=A\times R\sum_{i=1}^n\sum_{j=1}^mC_jQ_{i,j}r_i$$ | (3) |

I : Environmental impact (kg X-eq/year)

A : Bridge area (m2)

R : Maintenance area ratio (%)

Cj : Emission coefficient by material (kg X-eq/unitㆍyear)

Qi,j : Input material quantity (unit)

ri : Weighting factor (Frequency ratio by maintenance method)

n : Type of maintenance method

m : Type of input material

In equation (3), the value of the life cycle inventory database (LCI DB) established for each country (coefficient C) should be applied, and the remaining values should be applied by using the bridge maintenance database for each country. In this study, the global warming environmental impact due to the maintenance per unit area of bridge was calculated by analyzing the road bridge data and LCI DB emission coefficient data for Korea.

Based on road bridge maintenance data from Korea, the global warming impact of bridge maintenance was 2.71 kg CO2-eq/yearㆍm2, as shown in Table 5, which is a prediction of the global warming effect that occurs over 1 year for 1° m2 of bridge in Korea.

Table 5. Estimated global warming impact of bridge maintenance in Korea

In addition, environmental impact values, such as resource consumption, ozone layer effect, acidification, eutrophication, and photochemical oxide generation, were calculated by changing the emission coefficient from the model equation suggested in this study, shown in Table 6. These results are meaningful enabling the prediction of the environmental impacts that occur during the life cycle of a bridge before the occurrence of maintenance events.

Table 6. Estimated environmental impacts of bridge maintenance in Korea

Discussion

For bridge maintenance, data collected through the BMS in various regions, such as the US and Europe, can reveal meaningful maintenance information. Therefore, to derive an accurate equation model describing the bridge environmental impact, detailed management of bridge maintenance data is required.

In this study, the years of service of bridges, which may affect the maintenance performance of bridges were excluded from consideration; however, it is necessary to explore the relation between the maintenance effect and years of service of bridges. Actual bridge maintenance events can be caused by a number of variables; thus, it is difficult to consider them all. However, while many studies are conducted after the maintenance event of the structure, such as those performing the monitoring of bridges [16, 17, 18], this study uses past bridge maintenance information to predict the maintenance event before it occurs. This is a meaningful way to present prediction-making, allowing us to consider how to handle maintenance events in advance while simultaneously ensure the durability and eco-friendliness of the bridge.

This study evaluates the bridge environmental impact from the LCA perspective through the environmental impact calculation model proposed in this study. Furthermore, development of this study should continue to secure bridge durability and economic efficiency by establishing a bridge asset management system integrated with the life cycle cost (LCC) perspective.

Conclusion

In this study, we proposed a method for calculating the environmental impact of bridge maintenance through LCA. The frequency of major maintenance and the ratio of the maintenance area to the total area of bridges were calculated using bridge statistics and bridge maintenance datasets, and the input materials for each maintenance method were classified. Consequently, we proposed a model equation that predicts the environmental impact of bridge maintenance using the analyzed values, and calculated the environmental impact of the annual maintenance of Korean road bridges by applying the calculated values to the model equation.

By analyzing the dataset, maintenance methods were classified into maintenance, replacement, and reinforcement. A total of eight methods were selected as a result of extracting the major methods included in each method. The frequency of each method was analyzed from the dataset, and the ratio of the area in which the bridge maintenance was performed to the total area of the road bridges was calculated and used as a weighting factor in calculating the environmental impact.

The main input materials for each classified maintenance method were investigated, and a model equation was proposed that predicts the environmental impact of bridge maintenance by applying the quantity of main input materials and the weighting factor calculated through data mining and the environmental impact coefficient Life Cycle Inventory (LCI DB). The average annual environmental impact of Korean road bridge maintenance was calculated by reflecting the results analyzed through the maintenance datasets of the Korean road bridges.

As we can learn what will happen in the future by studying the information from the past, the equation model proposed in this study is meaningful because it can help us predict the environmental impact that will occur during the life cycle of the bridge before the maintenance events actually occur. It is expected to be used to secure durability and eco-friendliness at the planning and design stage of bridges.