Introduction

Literature Review

Previous studies on structure maintenance

Theoretical framework for environmental impact analysis

Establishment of the database of the environmental impact assessment of the polymer cement mortar filling method

Goal and scope definition

Life cycle inventory analysis

Establishment of the database of the environmental impact assessment of the polymer cement mortar filling method

Results of the environmental impact assessment

Conclusion

Introduction

The current global environmental problems, such as global warming, ozone layer depletion, and eutrophication, have been found to be primarily caused by carbon dioxide, nitrogen compounds, and acidic compounds released into the atmosphere as a result of increasing energy consumption due to continuing urbanization and industrialization. Of them, carbon dioxide, which has been identified as the main culprit, is increasing with increase in economic growth and living standards [1].

In an effort to solve these environmental problems, the international community has established collective goals in the “Rio Conventions” (results of the Earth Summit held in Rio de Janeiro in 1992) and the Kyoto Protocol (in full Kyoto Protocol to the United Nations Framework Convention on Climate Change) of 1997. Since then, the international community has been working together to reduce environmental load by achieving the goals set in the Kyoto Protocol [2]. To keep abreast of this international trend, the Korean government has strived to put in place an industrial system designed to reduce environmental load across all related industrial fields including energy, production, transportation, agriculture and livestock, forestry, and waste management. The construction sector is one of the industrial sectors exerting adverse influence on the environment due to the production of building materials in ever-increasing amount to meet the growing demand for large-scale buildings, residents’ energy consumption, renovation, demolition, and waste treatment. To counter such anti-environmental characteristics of the building industry, the government has put much effort into reducing the building-related environmental load such as enacting the Green Building Development Support Act and promoting retrofit of buildings to extend their service life. Research is also underway to establish a life cycle assessment (LCA) system, which encompasses the production and transportation of building material, construction, maintenance and management, and disposal, going beyond the scope of environmental load of the building itself [3].

Responding to the compelling need to reduce environmental load in the building industry, modern buildings contribute to the reduction of building-specific environmental load by means of eco-friendly design techniques and technology development. In this regard, research on building’s service life extension by means of maintenance and retrofit is the most basic research on raw material saving and environmental impact reduction throughout the LCA process. At the end of a building’s service life, it is demolished and discarded, and reconstruction begins. Demolition involves large-scale waste generation and energy use for operating heavy equipment operation, and reconstruction generates the same amount of environmental load as the initial construction. By contrast, if the building’s service life is extended through structure maintenance, the waste materials from demolition can be used for structural retrofit, thus saving the raw materials necessary for reconstruction. The materials required for maintenance would have much smaller environmental load compared with reconstruction. However, due to the current lack of an accurate quantitative estimation system for this process, this effect is not insufficiently recognized. Therefore, there is a need to develop an accurate method for quantitative environmental impact assessment in order to quantify the environmental load reduction resulting from the extension of a building’s service life by providing maintenance [4].

The purpose of this study is to establish a life cycle inventory (LCI) database of the polymer cement mortar filling method, one of the cross-section repair methods, as a sub-study of research on environmental impact reduction based on this maintenance method and to analyze the related environmental impact characteristics.

To this end, we selected a typical concrete structure repair site and performed the LCA for the entire input materials for the structure maintenance using the polymer cement mortar filling method, which is a cross-section repair method widely used on concrete structure repair sites, depending on the polymer/cement (P/C) ratio in accordance with the Korean Industrial Standard KS F 2476. The amount of input materials per unit construction area was used, thereby applying the schedule of rates for construction, and the LCA was performed on the calculated input materials on the basis of Korea LCI DB on input materials and the national LCI DB on environmental information of construction materials. Based on the LCA results, we compared the environmental impacts depending on the repair method.

Literature Review

Previous studies on structure maintenance

Overview of structure service life

Unlike general consumer products, buildings have long service lives, during which their functionality should be maintained well. Building maintenance including repair and rehabilitation is essential for keeping a building stable and durable and extending its service life. Durability of a building is its physical and structural properties and is directly related to its service life, which is the period during which the building and its facilities maintain their physical and structural functions [5].

Structure maintenance method

Unlike the finishing or equipment materials, the structural members cannot be easily replaced at the unit level. Therefore, it is crucial to maintain their function and improve a building’s service life through periodic structural inspection and diagnosis of their exterior and interior states. There are various structure maintenance methods depending on the type of repair need, taking into account the deterioration period and cause of damage (leakage, cracking, or durability loss through rebar corrosion). Depending on the damage diagnosis, various repair methods are used: general crack repair, rebar corrosion crack repair, surface protection against corrosion environment to prevent durability degradation, and cross-section repair of the parts damaged due to durability degradation [6]. Table 1 outlines the repair methods and materials for each repair category.

Table 1. Repair methods and major repair materials

Theoretical framework for environmental impact analysis

Assessment of the major 6 environmental impact categories

Global environmental problems began to emerge as a major issue in the late 1980s. Global environmental problems are usually assessed in major 6 categories: global warming potential (GWP), acidification potential (AP), eutrophication potential (EP), abiotic depletion potential (ADP), ozone depletion potential (ODP), and photochemical oxidant creation potential (POCP). These potentials for environmental impact indicate the level of reduction of the self-purification capacity of the earth due to anthropogenic pollutants. Continuous disturbances of nature and ecosystems by anthropogenic stressors are pointed out to be the major cause for the increasing degradation of the recovery potential of nature [7].

Environmental impact assessment methodologies

Environmental impact assessment refers to the process of quantifying the input resources and energy during the product life cycle (production, assembly, transportation, use, maintenance, and disposal) and evaluating their respective environmental impacts. It is used as a tool for setting up strategies for environmental load reduction and sustainable development. Environmental impact assessment consists of four phases of goal and scope definition, inventory analysis, life cycle impact assessment, and life cycle interpretation, based on the ISO 14000 Family of Standards (KS I ISO 14040), a series of standards developed by the International Organization for Standardization (ISO) to address environmental management.

① Goal and scope definition

In the goal and scope definition phase, the goal and scope of environmental impact assessment are set. Above all, it is of vital importance to set a clear scope of environmental load in terms of environmental impact categories taking into account the product system, function, and functional unit.

② Life cycle inventory analysis

In the inventory analysis phase, each of the input and output items of the target system is converted into the quantity of input and output materials by functional unit of production within the range of the goal and scope set in the previous phase.

③ Life cycle impact assessment

In the impact assessment phase, the interpretation range of the LCA is selected and the impacts of individual environmental impact factors collected in the inventory analysis phase are classified, normalized, and weighted, followed by a comprehensive assessment of the target system. Table 2 outlines the major 6 environmental impact categories and their respective assessment methodologies [3].

Table 2. Impact Factor methodology of major 6 environmental impact category

④ Life cycle interpretation

In the impact assessment result interpretation phase, environmental susceptibilities and advantages in the process are identified and strategies for reducing the environmental impact potentials of the factors determinant of the environmental load in their respective processes are proposed.

Establishment of the database of the environmental impact assessment of the polymer cement mortar filling method

Goal and scope definition

As the repair method we selected the polymer cement mortar filling method, which is a cross-section repair method widely used on concrete structure repair sites, in order to enhance the reliability of the environmental impact assessment of a concrete structure repair method [8]. The environmental impact assessment was performed on two types of polymer: styrene butadiene rubber (SBR) and ethylene vinyl acetate (EVA). In accordance with KS F 2476 (polymer-modified mortar test sample preparation method), we performed environmental impact assessment for polymer cement mortars of P/C ratios of 5, 10, 15, and 20. For the scope of data, we calculated the materials used for the method based on the mixing ratio and examined the LCI DB items of maintenance materials established by the direct estimation method. First, the database of major repair materials for each repair method was selected by analyzing the 2011 standard construction estimation and schedule of rates. Then we examined the current situation using a Korean LCI DB and abroad LCI DB based on the direct estimation method in order to calculate the characterized environmental impacts of maintenance materials. The Korean LCI DB was used as the primary reference, and the abroad LCI DB was used as supplementary data. As the basic assessment unit of establishing the LCI DB, we set 1 kilogram of cross-sectional repair material as the standard unit.

Life cycle inventory analysis

For the life cycle inventory analysis of the materials used in the polymer cement mortar filling method, we used a Korean LCI DB and abroad LCI DB. Table 3 presents the inventory of the input and output items of SBR.

Table 3. LCI DB of styrene butadiene rubber

Establishment of the database of the environmental impact assessment of the polymer cement mortar filling method

Analysis of the mixing ratios of the maintenance method

Table 4 presents the mixing ratios of the materials (polymer, cement, sand, and water) for the mortar used in the polymer cement mortar filling method.

Table 4. Mixture ratio of polymer cement (unit: g)

Analysis of the reference material and impact index analysis by environmental impact category

Environmental problems can be quantified by converting their values into their respective reference materials. We used the method proposed by the Ministry of Environment: the coefficient of each causative factor is calculated and multiplied by the mass of the causative substance per unit kilogram. Environmental impact materials occur in various areas such as resources, atmospheric, and water quality.

① Global warming potential (GWP)

CO2, CH4, and N2O are responsible for the greatest part of global warming. The GWP impact index can be calculated, with CO2 as the reference material (index value = 1), by converting CH4-2.5E+01 and N2O-2.98E+02 into their respective coefficients.

② Ozone depletion potential (ODP)

CFC (also known as Freon) is primarily responsible for the ODP. With CFC-11 as the reference material, the impact index can be obtained by multiplying the coefficients of CFC-114 and CFC-12.

③ Acidification potential (AP)

The coefficient of sulfur, the main cause of acidification, is calculated with SO2 as the reference material. The AP impact index is obtained by multiplying the coefficients of NOx, NH3, and HF.

④ Abiotic depletion potential (ADP)

For the calculation of the ADP impact index, we considered a total of 89 resource items including crude oil, natural gas, and Uranium (U) based on the standards presented by Guinee et al. (2001).

⑤ Eutrophication potential (EP)

NO3- and HNO3 are primarily responsible for EP, the coefficient of both gases is 1. Others include COD, NOX, and PO43-, and the EP impact index is calculated by multiplying their respective coefficients.

⑥ Photochemical oxidant creation potential (POCP)

A variety of substances including CO, Propane, and Sulfur are responsible for the POCP of the building sector. The POCP impact index is calculated by multiplying their respective coefficients.

Classification and characterization

We calculated the environmental impact indexes of the major input materials for concrete structure maintenance material in the production stages based on the reference material and impact index of each of the major 6 environmental impact categories (GWP, ODP, AP, ADP, EP, and POCP). For each environmental impact index, we used the database applied to the Korea Green Building Certification and performed classification and characterization based on the mixing ratio table of the polymer cement mortar filling method analyzed above. Classification consists of classifying and gathering steps according to the presented environmental impact categories. In the LCI DB established by gathering relevant national and international data, the impact materials are assigned to the environmental impact categories based on the facts extracted from the literature and the assigned data are gathered category by category, and their respective environmental impacts are quantified. Characterization is the process by which the environmental impact of each raw material is quantified. The characterized environmental impact can be derived by the sum of the product of the environmental load and impact index of each impact material, as expressed by Eq. (1).

| $$CI_i=\sum_{}CI_{i,j}=\sum_{}(Load_j\times eqv_{i,j})$$ | (1) |

where CIi is the size of the characterized environmental impact, Loadj is the environmental load of the impact material jth, and eqvi,j is the impact index of the impact material jth belonging to the impact category i. Table 5 outlines the values of the impact coefficients of the polymers SBR and EVA derived using Eq. (1).

Table 5. Environmental impact factor of SBR polymer and EVA polymer

Results of the environmental impact assessment

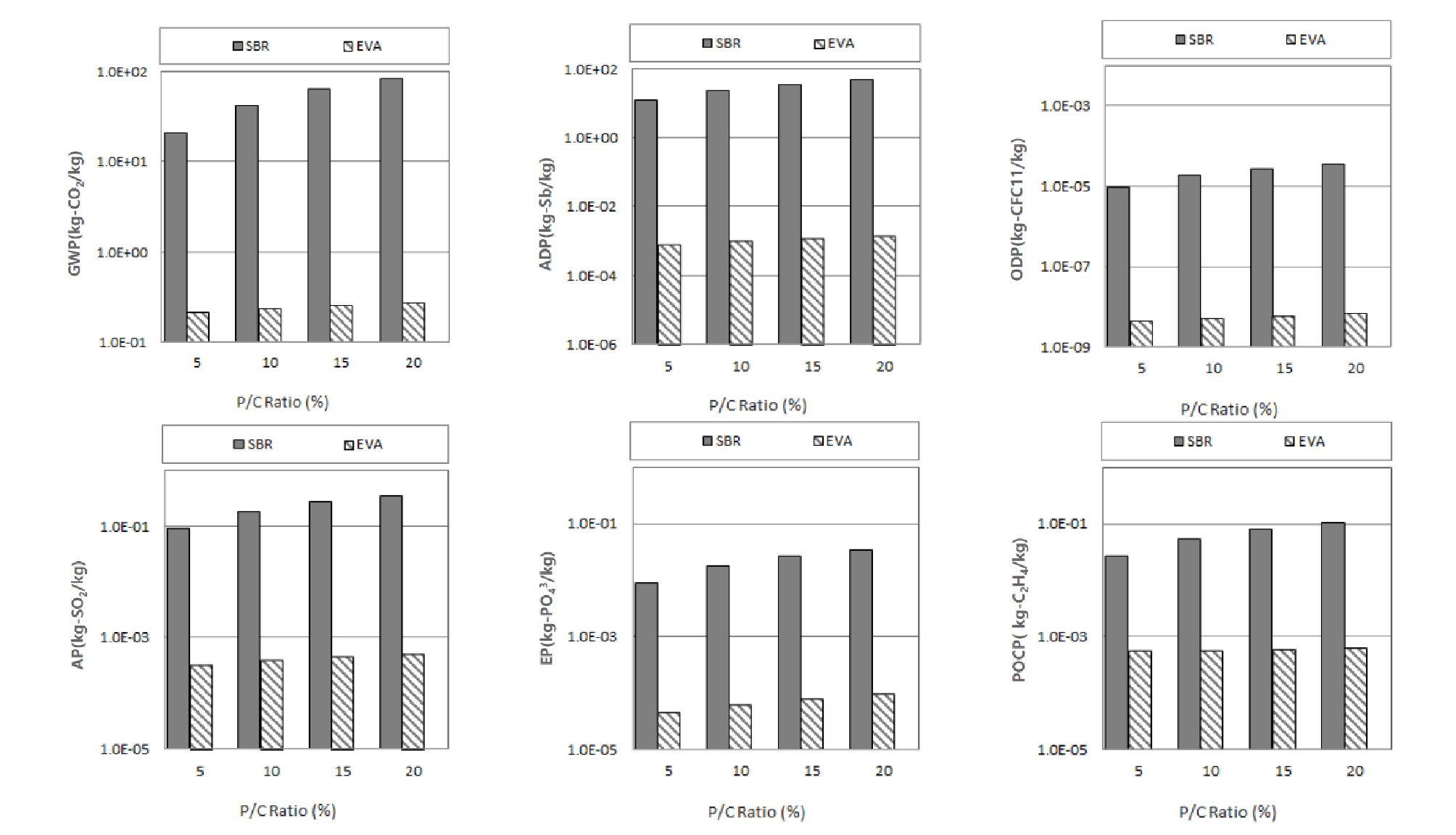

The results of environmental impact assessment based on the calculation as per Eq. (1) revealed that SBR has higher impact index than EVA in all six environmental impact categories (GWP, ODP, AP, ADP, EP, and POCP).

Figure 1 clearly demonstrates the differences between these two polymers. On the graph therein, the X-axis indicates the P/C ratio and the Y-axis indicates the environmental loads for the major 6 environmental impact categories. Figure 1 shows that SBR has a clearly higher overall index than EVA.

With respect to kg-CO2/kg, the GWP of SBR is 2.088E+01 at the P/C ratio of 5%, which increased to 4.157E+01, 6.226E+01, and 8.295E+01 at 10%, 15%, and 20%. The GWP of EVA was calculated to be 2.116E-01, 2.322E-01, 2.527E-01, and 2.733E-01 at the P/C ratios of 5%, 10%, 15%, 20%. The differences in these values can be checked against the LCA of each material.

Table 6 compares the component analysis of SBR and EVA. The analysis results revealed CO2 as the material with the largest difference in the GWP between the two polymers, with CO2 emission of SBR over 1000-fold higher than EVA (1.968E+03 vs. 1.795E+00).

The characterized ADP values with respect to kg-Sb/kg were also much higher in SBR than in EVA at the P/C ratios of 5%, 10%, 15%, and 20% (1.183E+01, 2.366E+01, 3.549E+01, and 4.732E+01 vs. 7.611E-04, 9.732E-04, 1.185E-03, and 1.397E-03). The main cause of this difference was the crude oil price, which makes up the largest portion of the ADP in both cases, resulting in the difference in the characterized value of the impact coefficients: SBR 5.848E+04 and EVA 9.234E-01.

Table 6. Comparison of global warming potential of polymer materials

The characterized ODP values with respect to kg-CFC11/kg at the C/P ratios of 5%, 10%, 15%, and 20% were calculated to be 9.111E-06, 1.822E-05, 2.733E-05, and 3.644E-05 for SBR and 4.258E-09, 5.038E-09, 5.817E-09, and 6.597E-09 for EVA. The average value of CFC-11, the ozone depletion impact materials emitted by both polymers, was much higher in SBR than in EVA (2.444E-06 vs. 4.394E-13).

The characterized AP values with respect to kg-SO2/kg at the C/P ratios of 5%, 10%, 15%, and 20% were calculated to be 8.710E-02, 1.739E-01, 2.608E-01, and 3.476E-01 for SBR and 3.232 E-04, 3.862E-04, 4.493E-04, and 5.123E-04 for EVA. The LCA analysis revealed the average value of Sulfur dioxide (SO2), the impact material for AP, was about 1000-fold higher in SBR compared with EVA (4.381E+00 vs. 3.823E-03).

The characterized EP values with respect to kg-PO43-/kg at the C/P ratios of 5%, 10%, 15%, and 20% were calculated to be 8.690E-03, 1.735E-02, 2.601E-02, and 3.468E-02 for SBR and 4.327E-05, 5.902E-05, 7.477E-05, and 9.052E-05 for EVA, demonstrating large differences. The LCA analysis revealed that the value of PO43- (impact coefficient = 1) for SBR was twice as high as that of EVA (0.003689 vs. 1.452E-03) and the value of NH3 having the second highest coefficient was also much higher in SBR than in EVA (1.028E-04 vs. 9.963E-06). The difference in the impact index can be interpreted as arising from the different environmental loads of these two materials.

The characterized POCP values with respect to kg-C2H4/kg at the C/P ratios of 5%, 10%, 15%, and 20% were calculated to be 2.657E-02, 5.262E-02, 7.867E-02, and 1.047E-01 for SBR and 5.437E-04, 5.662E-04, 5.886E-04, and 6.111E-04 for EVA. Analyzing the LCA of each polymer, no non-methane volatile organic compounds (NMVOCs) (impact coefficient = 1) were emitted, but the average value of benzene (impact coefficient = 0.218) was 3.600E-05 for SBR and 8.098E-07 for EVA. This can be interpreted as arising from the different characterized POCP values of these two materials.

Conclusion

This study aimed to establish a LCI DB of the polymer cement mortar filling method, one of the cross-section repair methods, as a sub-study of research on environmental impact reduction based on this maintenance method and to analyze the related environmental impact characteristics. The following summarizes the analysis process and results and presents the conclusion of this study:

1. We selected the polymer cement mortar filling method using styrene butadiene rubber (SBR) and ethylene vinyl acetate (EVA), two polymers commonly used for cross-section repair, and calculated the per-unit input materials for each repair method based on the construction schedule of rates and in accordance with KS F 2476.

2. The characterized values of the SBR and EVA polymer cement mortar filling methods were compared in each of the major 6 environmental impact categories (global warming potential, abiotic depletion potential, ozone depletion potential, acidification potential, eutrophication potential, and photochemical oxidant creation potential) based on a Korean LCI DB and abroad LCI DB.

3. The results of the environmental impact assessment of each method, comparing the characterized impact values in each impact category, revealed that SBR had higher values in all six categories compared with EVA. In particular, the characterized value for ozone depletion potential was over 1000-fold higher, and the two polymers showed over 100-fold difference in the impact index in all other impact categories.

4. These study results allow the conclusion that the EVA polymer cement mortar filling method is more eco-friendly than the SBR polymer cement mortar filling method for concrete structure maintenance purposes under the aspect of the major 6 environmental impact categories.