Introduction

Methodology

Life Cycle Assessment

Building Materials

Analysis of building main materials

Case Study

Result of Analysis

Conclusion

Introduction

Recently, in the field of architecture, modern urban society is confronted with many environmental problems, such as rapidly changing climate, securing energy supplies and stability of use [1], [2], [3]. As a result, there is a growing interest in environmental issues in buildings. Therefore, the importance of LCA, which quantitatively evaluates the amount of environmental impact that may occur in a building’s entire life cycle, from the production stage to the construction stage, operation stage, and disposal stage due to materials consumed in construction work, is increasingly important [4]. Particularly, the 2016 amendment of Korea’s Green Building Certification (G-SEED) includes materials and resources for innovative design [5]. Leadership in Energy and Environmental Design (LEED) and Building Research Establishment Environmental Assessment Method (BREEAM), which are widely recognized as a major technique in the field of eco-friendly building design and construction [4]. However, although the LCA evaluation of the building should be made at the design phase, it is not easy to compile because of frequent design changes and a large amount of data in the design stage [6]. In addition, due to the nature of the construction industry in Korea, the number of LCA cases for non-residential buildings was relatively small, as there were many cases of residential building demand and related certification than non-residential buildings [7]. Therefore, there has been a demand for a technique that can more easily perform LCA of a building. For this reason, this study identifies the major building materials for each use and type of building as a part of the research to support the evaluation of the whole life cycle of the building, and based on this, the life cycle evaluation was done.

As a result, this study derives major building materials needed for LCA and improves the process of LCA more efficiently to find environment-friendly building LCA.

Methodology

This study aims at identifying major construction materials from the viewpoint of LCA of buildings. In order to secure the reliability of the resulting products, major construction materials were analyzed using the cut-off criterion of 99% cumulative weight contribution according to the international standard ISO 14040s LCA and G-SEED LCA [5], [8].

The analysis includes thirty-two types of non-residential buildings, including business buildings and general buildings, which are constructed in Korea. Based on the design book and the quantity calculation statement for the thirty-two building cases, the input amounts of the building material was understood. After that, all of the input quantities were converted into weight per unit area (ton), the weight contribution percentage was calculated, and the main building materials with a contribution rate of 99% were selected.

Life Cycle Assessment

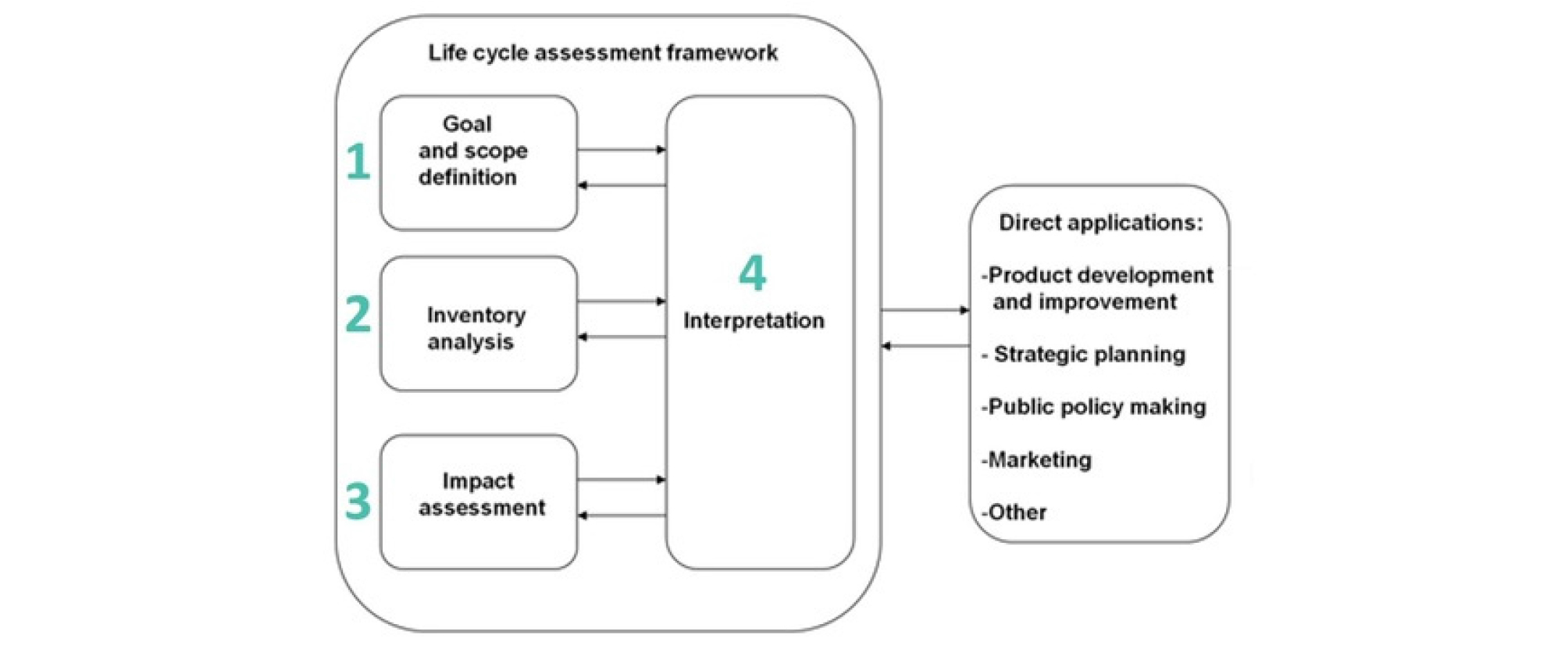

In the industrial sector, LCA is applied as an environmental evaluation tool and as an environmental load assessment technique [9]. These have been an important technique for evaluating buildings since the 1990s [10], [11]. From the perspective of LCA, the construction industry consists of production, construction, operation and disposal phases. Life Cycle Assessment is a technique to quantify and record the environmental pollutants emitted and the resources and energy used in the process, to identify and evaluate the potential adverse effects on the environment, and to reduce and improve them. Through the ISO 14040 series, products are increasingly held to environmentally friendly design and environmental claims, environmental accounting, process improvement, public policy establishment, marketing, and decision making [12]. The LCA consists of four stages: 1. Goal and scope definition; 2. Life Cycle Inventory analysis; 3. Life Cycle Impact Assessment and 4. Life Cycle Interpretation.

The goal and scope definition is the first step in the LCA. At this stage, consideration should be given to the type of information used to make the decision, the accuracy of the results, and how the results of the whole process assessment are interpreted.

The Life Cycle Inventory analysis is a process to record and list all the raw materials and energy that are put into the products and the kinds and amounts of the by-products and environmental pollutants that are set in the goal and scope definition. And the main purpose is to collect input and output data for each process.

Life Cycle Impact Assessment is an essential element in assessing environmental aspects in the life cycle assessment. Life Cycle Impact Analysis aims to quantitatively or qualitatively assess the degree of environmental impact by linking specific environmental impacts and inventory items based on inventory analysis.

Life Cycle Interpretation is the step of evaluating and interpreting the results of the list analysis and the impact assessment, alone, or in combination. The results of the analysis are the conclusions about the purpose and scope of the LCA, and actions are taken on the basis of these results when the environment is improved.

The system for LCA described above is shown in Figure 1. The phases are often interdependent in that the results of one phase will inform how other phases are completed.

Building Materials

In order to analyze the major building materials of the non-residential buildings covered by this study, five types of non-residential buildings classified in G-SEED were analyzed: business facilities, general buildings, educational research facilities, accommodation facilities. Of the thirty-two buildings, except for the accommodation, sales and educational facilities, which are in low demand. In order to calculate the actual quantity, we classify the materials used in the construction work, the construction method, and the auxiliary materials. Then, according to the cut-off criteria analysis method, the main building materials were analyzed. The weight-based exclusion criterion analysis method is defined in the ISO 14040 series, the international standard for LCA. This standard analysis method is a criterion that can quantitatively exclude certain materials in the process of input evaluation of life cycle evaluation.

In the study, the life cycle assessment was carried out using the design book and the quantity calculation statement for the case building for two commercial and non - residential buildings. In order to ensure consistency, all units of materials are converted into weight (ton) because the quantity calculation for buildings is different for each material. The construction unit conversion factor applied in terms of weight unit refers to Korea’s standard construction cost of building construction, building specification, and metal weight, since the construction material used in the construction work is reused at other sites after use. In addition, auxiliary materials and work-by-products that account for less than 0.01% of the total weight of the non-residential building construction were excluded from the scope of analysis. Table 1 shows an example of the unit conversion factor of building materials applied in this study.

Table 1. Construction Material Unit Weight

| Material | Weight | Unit | Source |

| Reinforced Concrete | 2,400 | kg/m3 | Korea Construction Standard [14] |

| Cement Mortar | 2,100 | kg/m3 | Korea Construction Standard [14] |

| Cement | 40 | kg/bag | Korea Construction Standard [14] |

| Aluminum | 2,699 | kg/m3 | Metal Weight |

| Fiber insulation | 64 | kg/m3 | KS L 9102 [15] |

Analysis of building main materials

Table 2 shows the main building materials based on the weight of the two building types. There are fifteen kinds of general buildings and seventeen kinds of business buildings. Among them, there are seven kinds of RC structures and twenty-five kinds of SRC structures. Each material is expressed as a percentage of the total weight after conversion to weight. Table 2 shows the cumulative weight contribution corresponding to the exclusion criterion 99%. As shown in Table 2, there is a slight difference in the weight ratio or ranking of the major building materials depending on the size of the building, the floor area, and the type of building. However, if we judge only by the type of building materials, all buildings include common materials such as concrete, steel, steel, glass, brick, cement and aggregate. In particular, it has been confirmed that the ready mixed concrete has a high weight contribution of 82% or more in all cases.

Table 2. Result of Main Materials Analysis

Case Study

In this study, by analyzing tendency of major materials used in actual construction for general buildings, business buildings, RC structures, and SRC structures through thirty-two cases, we identified the main building materials that can be used for LCA. Therefore, in this chapter, it is verified whether the life course evaluation can be carried out only by the materials derived from the study, in contrast with existing buildings, in order to secure the reliability of the result.

The analysis target is a RC structure general building in Gyeongsangbuk-do, Korea, and a SRC business building in Seoul. Verification of major materials for each application derived for each building and verification of RC structure and SRC structure main materials for general buildings and business buildings. Table 3 shows the outline of the analysis target.

Table 3. Overview of Analysis target

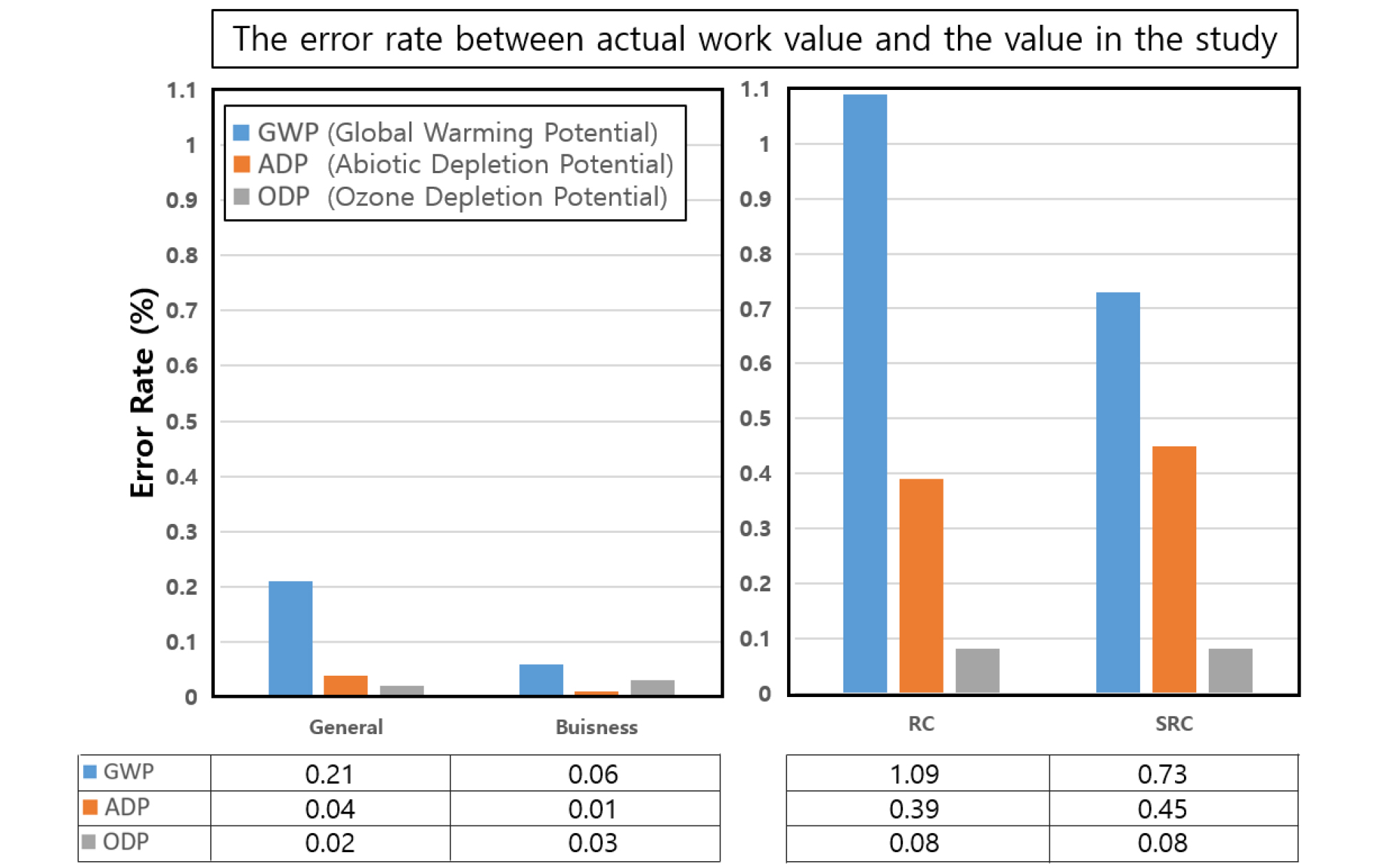

As a method of verification, this study analyzes the errors by comparing the results of the LCA performed with the materials with the 99% weight contribution of the case analysis and the results obtained from the study. The comparison of the evaluation results is performed for three environmental impact categories including the Global Warming Potential (GWP), which is the guideline of G-SEED, the Korean green building certification system. Therefore, the emission figures for GWP, Abiotic Depletion Potential (ADP) and Ozone Depletion Potential (ODP) among the six environmental impact categories defined in ISO 14025 [16] are compared and verified.

Prior to the verification, the construction phase in the life cycle assessment process is divided into the construction process and the transportation process; and the operation phase is divided into the replacement process and the operation energy process. The environmental impacts that occur during the transportation process in the construction phase are generated during transportation of the materials by the supply truck. Since the construction process occurs in construction using materials, there is no significant difference between existing and major materials. Likewise, the operating phase is independent of the material, and the environmental impact is assessed by the amount of operating energy, and the replacement process depends on the presence or absence of tiles, the main material to be replaced during operation, but the effect is minimal and does not cause any significant differences. In the analysis result, no numerical difference was seen in the construction and operation stages, so we decided to compare the production and disposal phases.

Result of Analysis

Table 4 shows that the error rate is less than 3% over the entire life cycle of general buildings and Business buildings, in case verification of existing buildings. This result can be interpreted as a meaningful result with no significant difference compared to the existing LCA results when LCA is performed with only the key material derived from this study. Less than 3% over the entire life cycle, less than 0.3% for the total emission amount, and 0.06% for the average, which can be used in the life cycle assessment only for the major materials derived for each application. However, the LCA results of the major materials in Table 5 are different from those of the building materials used in the previous analysis. In the environmental impact analysis of the RC structure, the error rate was 16.01% in the GWP production stage and 25.30% in the ADP production stage. The results of the analysis of the SRC structure show that the error rate of 6.77% at the production stage of GWP was at least two times to eight times higher than that of other comparative analysis results of less than 3%.

Table 4. Comparison Analysis of Environmental Impact Emissions (1)

Table 5. Comparison Analysis of Environmental Impact Emissions (2)

The left and right charts in Figure 2 show the error rates of buildings by structure and structures by usage. As mentioned above, the error rate of buildings according to usage shows a small error rate of less than 0.2%, and it can be used even in practice. On the other hand, the structure-specific buildings have a relatively high error rate. This is because it is difficult to analyze the specific tendency of the use of building materials by structure in all applications, and the fact that thirty-two buildings as samples may not be sufficient to draw definitive results.

Conclusion

The purpose of this study is to analyze the major construction materials for building LCA as a part of the study to support the dissemination of LCA of green architecture certification system in Korea. As a result, the following conclusions were obtained:

1) The main building materials were derived for two kinds of non - residential buildings, and the main materials were derived for the two types of structures in structural form. As a result, nine kinds of major materials including general building, commercial building, RC structure and SRC structure including five kinds of common materials, such as concrete, steel, steel, glass and brick, four kinds of different materials were derived.

2) In order to verify the applicability of the existing building materials’ life cycle assessment methodology, this study was conducted to investigate the applicability of GWP, ADP, and ODP.

3) As a result of the Case Study, the main materials of the building for each purpose derived from the weight basis showed a margin of error of less than 3% in the evaluation of the materials of the existing buildings and in the entire life cycle, and significant values were obtained. Compared to the total environmental impact, the error rate is less than 0.3% and it is analyzed that it is applicable to the environmental impact assessment in the life cycle assessment.

4) A large error rate was analyzed at the production stage of GWP and ADP when applying the major materials derived from the analysis of structure by structure. It is possible to make two inferences that cannot analyze the tendency of input materials of various types of buildings by the point that thirty-two buildings to be analyzed are not enough to draw tendency and by structure.

Therefore, it can be expected that LCA of general buildings and commercial buildings can be evaluated more efficiently in terms of time and cost by using the major materials derived from this study.

There are five kinds of non-residential buildings defined by G-SEED: educational research facilities, sales facilities, accommodation facilities, general buildings, and business buildings. If this study wishes to contribute to the dissemination of LCA, all five kinds should be studied in addition to the two kinds studied in this study. To do this, data on the overall LCA performance should be collected and stored. It is also necessary to study the complementary measures that can reduce the precision and errors of specific cases through the accumulation of verification data on the main materials and general cases derived from the research.